POSrobo Automation –

The Ingenious Solution for Efficient Automation

Revolutionize your production with the innovative POSrobo automation solutions. Our patented systems integrate seamlessly into your POSmill machining centers and enable demand-oriented, step-by-step automation without overinvestment. From the unique "invisible" solution in the tool changer for small parts to the flexible external unit for large parts - POSrobo adapts precisely to your requirements.

Internal solution that utilises the tool changer: POSrobo R74 | R 125

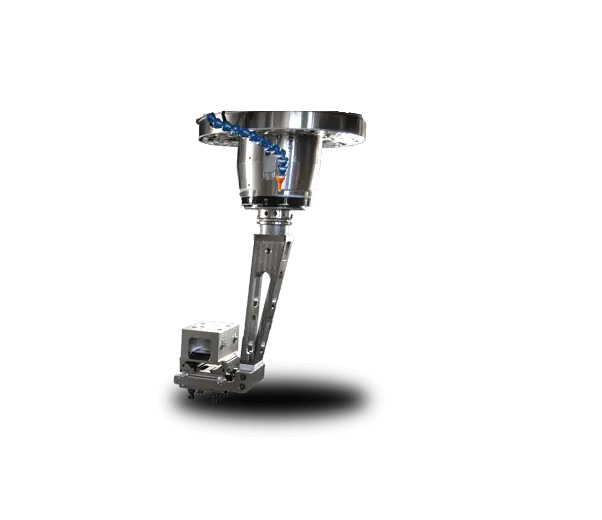

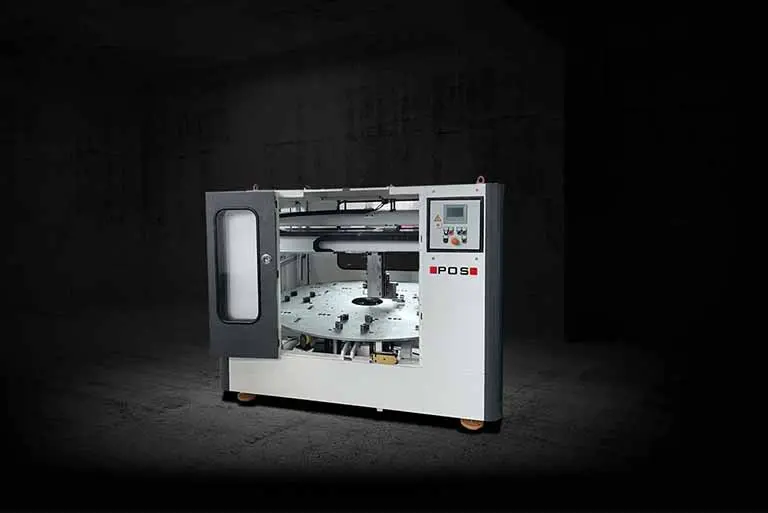

Compact and space-saving: POSrobo R 500

Main time-parallel loading of components (R 74 | R 125)

Simple and efficient couplings for every pallet size (R 500)

Oversizes can also be moved practically (R 74 | R 125)

Oversizes can also be moved practically (R 500)

Easy to retrofit without requiring additional space (R 74 | R 125)

Optimum loading of heavy parts through the loading hatch (R 500)

Clever "CAN Automation" for all POSmill machining centers: Flexible, space-saving, and extremely cost-effective!

With the innovative POSrobo automation solutions, POS offers a revolution in manufacturing automation. Our patented systems enable flexible, demand-oriented, and cost-efficient automation of your POSmill machining centers - without the risks and costs of rigid "all-or-nothing solutions".

- Unbeatable cost efficiency: Up to 65% lower investment compared to conventional solutions • Amortization even with a low degree of automation • Investment under 40,000 € for small parts automation (POSrobo R 125)

- Maximum flexibility: Scalable solutions: 6 to 118 pallets, transfer weight up to 350 kg • Demand-oriented automation: Use the advantages only when economically viable • Full accessibility to the machine for manual operation

- Innovative integration: "Invisible" automation by using the tool changer (POSrobo R 74 / R 125) • No additional space requirement for small parts automation • Seamless connection to all POSmill machining centers

- Easiest operation: Control via the familiar POSmill machine control • High employee acceptance through known processes • Minimal training effort

- Future-proof investment: Modular design allows step-by-step expansion • Retrofittable for all POSmill machining centers from generation 2 • Preparation for Industry 4.0 and networked production

- Holistic solution from a single source: Perfect coordination with POS clamping devices and zero-point clamping systems • One contact person for machine and automation • CE-compliant as a complete solution

From efficient small series to highly productive large-scale production: POSrobo grows with your requirements

- Efficient series production: Challenge: Increasing quantities with simultaneous cost pressure • Solution: POSrobo R 500 with up to 30 pallets for unmanned production

Your benefit:

- Production around the clock with full accessibility for personnel

- Significant reduction of unit costs without overinvestment in rigid systems

- Flexible adaptation to fluctuating order situations

- Agile small series and prototype production: Challenge: Frequent setups and small batch sizes • Solution: POSrobo R 74 / R 125 with flexible pallet allocation

Your benefit:

- Efficient automation even for batch size 1

- Drastic reduction of setup times

- Increased competitiveness through faster response to customer requirements

- Complex 5-axis machining: Challenge: Precise production of complex components with long runtimes • Solution: POSrobo + POSmill 5-axis machining centers

Your benefit:

- Unmanned complete machining in one clamping

- Highest precision even with long runtimes

- Optimal utilization of high-quality 5-axis machines

- Flexible parts production: Challenge: Wide range of parts with fluctuating demand • Solution: Modular POSrobo system, scalable from 6 to 118 pallets

Your benefit:

- Demand-oriented automation without overinvestment

- Fast amortization through optimal utilization

- Future-proofing through easy expandability

Optimal symbiosis of performance and cost-effectiveness

POSrobo automation solutions pay for themselves, unlike rigid interlinking, even with a low degree of automation. They enable a quick return on investment without incalculable risks. At the same time, you retain full control over your production and can intervene manually at any time. With POSrobo, you not only increase your productivity but also your competitiveness. The clever "CAN Automation" flexibly adapts to your current requirements and grows with your company.

Amortisation POSrobo R 74 vs. conventional automation

Our promise of fairness:

Automation that pays off

At POS, we prioritize honest advice over a blind rush to automate. We carefully check whether automation is really worthwhile for you. Our rule of thumb: The price of automation should not exceed 20% of the value of your machining centre. This enables you to achieve a fast ROI and increase your productivity and margin - without overinvesting. The result: more profit and the opportunity to remunerate your skilled workers better. Benefit from our experience for a customised, economical automation solution.

Automating with POS

POSrobo: High-end equipment for maximum flexibility and efficiency

The POSrobo automation solutions offer a variety of well-thought-out features that make your production more efficient, flexible, and simpler. From seamless integration into your POSmill machining centers to free pallet configuration to extremely fast double gripper workpiece change: Everything is perfectly matched to each other and to your requirements for maximum productivity.

Technical excellence for every application

POSrobo R 125 & R 74 - Ingenious solutions for small parts:

- Part size max.: 200 x 150 x 200 mm (R 125) / 74 x 120 x 80 mm (R 74)

- Pallet size max.: 200 x 150 mm (R 125) / 74 x 120 mm (R 74)

- Number of pallets max.: 118 (R 125) / 60 (R 74)

- Transfer weight max.: 25 kg (R 125) / 6 kg (R 74)

- Compatibility: All POSmill series (CE-, E-, H-series)

- Retrofittability: Yes, from generation 2

- Special feature: Use of the tool changer, no additional space requirement

POSrobo R 500 - Flexibility for large parts:

- Part size max.: 500 x 500 x 500 mm

- Pallet size max.: 500 x 500 mm

- Number of pallets max.: 6 (expandable to 30)

- Transfer weight max.: 350 kg

- Compatibility: CE-, E-, H-series

- Retrofittability: Yes

- Space requirement min.: 2,000 x 2,600 x 1,600 mm

Common high-end features of all POSrobo models:

- Freely definable pallet types for maximum flexibility

- Innovative screw head coupling for fast, tool-free pallet replacement

- Control via the familiar POSmill machine control

- Main time parallel setup for optimized processes

- Perfect match with POS clamping devices and zero-point clamping systems

Automation solutions for every production requirement: POSrobo

POSrobo R 74 | R 125

The ingenious solution for small parts –

Automation differently!

Space-saving internal solution that utilises the tool changer.

Patented compatible with all POS machines

POSrobo R 500 (i) | R 400

External unit for large parts –

Automation differently!

Range up to 3 m up to 350 kg transfer weight.

Compatible with all POS machines.

Almost 50 years of expertise: Your reliable partner for innovative automation solutions.

As an expert in CNC machining centres and automation solutions, POS combines the highest manufacturing quality ‘engineered in Germany’ with personal customer service and tailor-made solutions for SMEs. Benefit from short decision-making paths and pragmatic support in every project phase.

We are like you: medium-sized and customer-orientated

"For almost 50 years, we have been focusing on the needs of our customers in the fields of parts production, special machine construction, and tool and mould making. This experience flows into every one of our CNC machining centres. We know what matters: highest quality, reliability, and service that won't let you down. With over 1,200 satisfied customers and more than 2 million machine hours in the market, we are your reliable partner for the future."

- We solve 65% of all downtimes already in the free telephone support. Even on weekends.

- 25 service technicians nationwide with their own mobile spare parts warehouse ensure quick help on-site.

- Spare parts worth 6.5 million EUR are always available in our warehouse to ensure maximum availability of your machines.

- 5 µm positioning accuracy according to DIN EN ISO 230 guarantee highest precision.

Ready for CAN instead of MUST automation?

Request your individual quote for the POSrobo automation solution now and secure a personal consultation! Our experienced experts will be happy to show you how to optimally benefit from the innovative features of POSrobo and together we will develop the perfect automation strategy for your application.

Increase productivity with POSrobo:

- Significantly lower investment, higher flexibility, and shorter ROI compared to conventional solutions

- Seamless integration into your POSmill machining centres: no additional space required, no risks for your overall system

- Quick and easy start to cost-effective complete machining thanks to optimised preparation and compatibility with POSmill

- Comprehensive expertise for your automation project with almost 50 years of experience in machine tool construction

- Partnership-based support with personal, competent contacts - even in the long term after commissioning

1 optional | * required

Our offer is aimed at business customers. We respect your privacy and process your data exclusively within the framework of a business customer relationship. Your data will be securely managed in accordance with our privacy policy.

Or simply call:

Discover all powerful machining centers and automation solutions from POS – Full equipment as standard!

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All machining centres (milling machines and lathes) can be expanded with our POSrobo automation solutions.