A POS 5-axis machining center protects your tools, increases your machine hours and creates process reliability –

affordable & with the best service.

Future-proof thanks to full equipment.

With a POS 5-axis machining center, you can secure new orders and ensure your company’s long-term success:

- High-end control is standard equipment:

- Choice of: Siemens One | Heidenhain TNC 640 / TNC 7

- 90 % German quality components

- Proven to be up to 35 % more stable and 4 x more precise

- Own patented automation solution

- Functioning, competent & fair service

- In-house financing without paperwork

POS: Milling machines, automation & lathes engineered in Germany

A POS 5-axis machining center protects your tools, increases your machine hours and creates process reliability –

affordable & with the best service.

Future-proof thanks to full equipment.

This is how you can secure new orders with a 5-axis POSmill and ensure the long-term success of your company:

- High-end control is standard equipment:

- Siemens One | Heidenhain TNC 640 | Fanuc 32iTB

- 90 % German quality components

- Proven to be up to 35 % more stable and 4 x more precise

- Own patented automation solution

- Functioning, competent & fair service

- In-house financing without paperwork

These are our

5-axis machining centers:

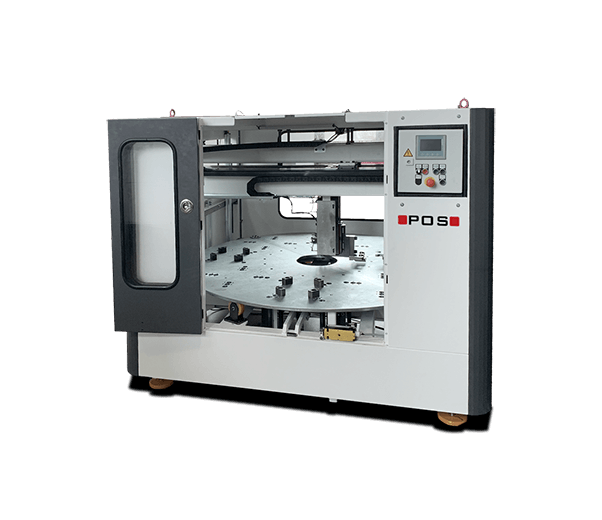

POSmill H 500 U

Our quick-change artist.

Travel (x, y, z)

650 | 850 | 500 mm

Swivelling range

+/- 120 degrees

Table size

400 | 500 | 600 mm

Speed (rpm)

18.000

Tool changer

80-fold, 120-fold

Machine weight

13 tons

Control system

Heidenhain TNC 640, Siemens One

Machine concept

Gantry design; Cast steel in the base body ensures uniform thermal behaviour; Top-mounted linear axes are subject to almost no dirt accumulation; Large bearings of the rotary axes integrated in the base body; Maximum rigidity due to design and YRT bearings; Optimum chip removal – almost without flushing; 4 linear guides in the Y-axis; Quick change of the table plate

Interior space

Completely stainless steel: Avoidance of edge transitions and funnel shape ensure optimum chip fall; automatic convertible top; flushing of the front doors via M function

Fully equipped

High-end control, large IKZ system, Heidenhain glass scales, electronic handwheel, water gun, air at the table or air through the spindle and much more.

Price

Compared to the competition, you need up to 30% less investment for a POS. All this with a functioning, competent and fair service. Compare us: We will make you a customised offer.

POSmill H 800 U

Our all-rounder with safety reserves.

Travel (x, y, z)

670 | 820 | 600 mm

Swivelling range

+/- 120 degrees

Table size

800 mm

Speed (rpm)

18.000

Tool changer

96-fold, 120-fold

Machine weight

20 tons

Control system

Heidenhain TNC 640, Siemens One

Machine concept

Gantry design; cast steel in the base body ensures uniform thermal behaviour; top-mounted linear axes are subject to almost no dirt accumulation; large bearings of the rotary axes integrated in the base body; maximum rigidity due to design and YRT bearings; optimum chip removal – almost without flushing

Interior space

Completely stainless steel: Avoidance of edge transitions and funnel shape ensure optimum chip fall; automatic convertible top; flushing of the front doors via M function

Fully equipped

High-end control, large IKZ system, Heidenhain glass scales, electronic handwheel, water gun, air at the table or air through the spindle and much more.

Price

Compared to the competition, you need up to 30% less investment for a POS. All this with a functioning, competent and fair service. Compare us: We will make you a customised offer.

POSmill H 2200 U

Large & highly profitable.

Travel (x, y, z)

2.200 | 1.400 | 1.000 mm

Swivelling range

+/- 120 degrees

Table size

1.200 mm

Speed (rpm)

18.000

Tool changer

90-fold, 200-fold

Machine weight

30 tons

Control system

Heidenhain TNC 640, Siemens One

Machine concept

Portal design; cast steel in the base body ensures uniform thermal behaviour; torque drive; integrated rotary table supplements 5th axis; tool insert up to 1,250 mm long; interference circle of 1,900 mm enables machining of oversized parts

Interior space

Large parts – large interior space: wide windows in the X-axis direction; reduced chip nests: 2 chip conveyor traps on both sides of the table discharge directly into ascending conveyors; safe step grids; collision-free tool change in the horizontal spindle position

Fully equipped

High-end control, large IKZ system, Heidenhain glass scales, electronic handwheel, water gun, air at the table or air through the spindle and much more.

Price

Compared to the competition, you need up to 30% less investment for a POS. All this with a functioning, competent and fair service. Compare us: We will make you a customised offer.

Affordable & with the best service – we put our 5-axis machining centres to the test

Enquire about one of our 5-axis milling machines with no obligation and compare POSmill with the competition: you can save up to 30% on your investment, as we offer you full equipment even in the basic version. Combined with the best and fairest service, your POS will accompany you profitably for a long time.

POSmill H 500 U

Our quick-change artist.

Travel (x, y, z)

650 | 850 | 500 mm

Swivelling range

+/- 120 degrees

Table size

400 | 500 | 600 mm

Speed (rpm)

18.000

Tool changer

80-fold, 120-fold

Machine weight

13 tons

Control system

Heidenhain TNC 640, Siemens One

Machine concept

Gantry design; Cast steel in the base body ensures uniform thermal behaviour; Top-mounted linear axes are subject to almost no dirt accumulation; Large bearings of the rotary axes integrated in the base body; Maximum rigidity due to design and YRT bearings; Optimum chip removal – almost without flushing; 4 linear guides in the Y-axis; Quick change of the table plate

Interior space

Completely stainless steel: Avoidance of edge transitions and funnel shape ensure optimum chip fall; automatic convertible top; flushing of the front doors via M function

Fully equipped

High-end control, large IKZ system, Heidenhain glass scales, electronic handwheel, water gun, air at the table or air through the spindle and much more.

Price

Compared to the competition, you need up to 30% less investment for a POS. All this with a functioning, competent and fair service. Compare us: We will make you a customised offer.

Affordable & with the best service – we put our 5-axis machining centres to the test

Make a non-binding enquiry about our POSmill H 500 U and compare POSmill milling machines with the competition: You can save up to 30% on your investment, as we offer you a fully equipped basic version. Combined with the best and fairest service, your POS will accompany you profitably for a long time.

POSmill H 800 U

Our all-rounder with safety reserves.

Travel (x, y, z)

670 | 820 | 600 mm

Swivelling range

+/- 120 degrees

Table size

800 mm

Speed (rpm)

18.000

Tool changer

96-fold, 120-fold

Machine weight

20 tons

Control system

Heidenhain TNC 640, Siemens One

Machine concept

Gantry design; cast steel in the base body ensures uniform thermal behaviour; top-mounted linear axes are subject to almost no dirt accumulation; large bearings of the rotary axes integrated in the base body; maximum rigidity due to design and YRT bearings; optimum chip removal – almost without flushing

Interior space

Completely stainless steel: Avoidance of edge transitions and funnel shape ensure optimum chip fall; automatic convertible top; flushing of the front doors via M function

Fully equipped

High-end control, large IKZ system, Heidenhain glass scales, electronic handwheel, water gun, air at the table or air through the spindle and much more.

Price

Compared to the competition, you need up to 30% less investment for a POS. All this with a functioning, competent and fair service. Compare us: We will make you a customised offer.

Affordable & with the best service – we put our 5-axis machining centres to the test

Make a non-binding enquiry about our POSmill H 800 U and compare POSmill milling machines with the competition: You can save up to 30% on your investment, as we offer you a fully equipped basic version. Combined with the best and fairest service, your POS will accompany you profitably for a long time.

POSmill H 2200 U

Large & highly profitable.

Travel (x, y, z)

2.200 | 1.400 | 1.000 mm

Swivelling range

+/- 120 degrees

Table size

1.200 mm

Speed (rpm)

18.000

Tool changer

90-fold, 200-fold

Machine weight

30 tons

Control system

Heidenhain TNC 640, Siemens One

Machine concept

Portal design; cast steel in the base body ensures uniform thermal behaviour; torque drive; integrated rotary table supplements 5th axis; tool insert up to 1,250 mm long; interference circle of 1,900 mm enables machining of oversized parts

Interior space

Large parts – large interior space: wide windows in the X-axis direction; reduced chip nests: 2 chip conveyor traps on both sides of the table discharge directly into ascending conveyors; safe step grids; collision-free tool change in the horizontal spindle position

Fully equipped

High-end control, large IKZ system, Heidenhain glass scales, electronic handwheel, water gun, air at the table or air through the spindle and much more.

Price

Compared to the competition, you need up to 30% less investment for a POS. All this with a functioning, competent and fair service. Compare us: We will make you a customised offer.

Affordable & with the best service – we put our 5-axis machining centres to the test

Make a non-binding enquiry about our POSmill H 2200 U and compare POSmill milling machines with the competition: You can save up to 30% on your investment, as we offer you a fully equipped basic version. Combined with the best and fairest service, your POS will accompany you profitably for a long time.

All POS machining centers can be expanded with our own automation solutions:

POSrobo R 74 / 125

Patented. The standard tool changer changes tools and workpieces. Compatible with all POS machines.

| Machine weight | up to 25 kg |

| Clamping type | Raw part or via zero-point clamping system |

| Retrofitting | at any time |

| Parts size | Everything that fits into a tool changer. For example, a 300 mm long strip can also be clamped in as a blank. We can design and define this together during project planning. |

| Number of positions | up to 120 – depending on the tool changer size |

| Machine types | All POS machines – Depending on the machine type, the function is extended or restricted. |

| Investment | minimal |

POSrobo R 500

The strong one for large parts. Range up to 3 m & compatible with all POS machines.

| Machine weight | up to 350 kg |

| Clamping type | Zero point clamping system |

| Retrofitting | at any time |

| Parts size | The largest pallet can be approx. 500 x 500 mm. However, the parts can be oversized. |

| Number of positions | Up to 30 storage locations. Depending on part size |

| Machine types | All POS machines |

| Investment | medium |

Full equipment is our basic equipment

We already have almost every conceivable option in the standard equipment of our machining centres. This way, no process-safeguarding elements are omitted. In addition, you can easily add the right automation solution to your machining center even later.

HIGH-END:

Premium control

We equip our POS machining centres with the Siemens Sinumerik ONE or the Heidenhain TNC 640 as standard.

MORE STABLE:

35 % more mass

POS milling machines are over a third heavier than the competition because we only use cast steel in the base body.

MORE PRECISE:

4 times higher resolution

4 times higher resolution The best Heidenhain glass scales (LC 115) as standard ensure extreme precision, process reliability and fulfil DIN EN ISO 230 with 5µm.

ROOMIER:

50 % more space in the tool changer

Up to 60 tool changers in our 3-axis machining centres and up to 200 tool changers in our 5-axis machining centres offer significantly more space than the competition.

BETTER PREPARED:

Automation

With air connection on the table, all our milling machines are equipped for automation. With the solution of your choice or our patented POSrobo R 74 / 125.

MORE PARTNERSHIP:

Fair & competent service

Our streamlined portfolio ensures service expertise: We know all our machines. And we solve 65 % of all downtimes with free telephone support.

90 % German quality components –

even in the basic version

Make the comparison! You will receive a customised calculation. Whether DMG, Haas, Mazak, Doosan, Okuma, Grob, Matsuura or whoever - compare our offer for a POSmill machining centre with the corresponding equipment from our competitors:

Standing still is not an option –

our service can do more

FREE OF CHARGE:

Solutions over the phone

With experienced telephone diagnostics, we solve around 65 % of all downtimes without an on-site visit. This saves time as well as money: Because this support is free of charge for you and ensures that your machine is ready for use quickly.

ANY TIME:

Service 7 days a week

We don't use any answering machines. As the owner of a POS machine, you can always reach our service team directly - even at weekends. Just as you are there for your customers, POS is always there for you!

KNOW-HOW:

We know our machines – all of them

You will never have to wait for one specialist again! Thanks to our streamlined portfolio, we have ensured that there is always a competent employee on hand who is fit for your machine.

NUMEROUS:

Our own team of service technicians

POS has 25 highly qualified service technicians ready to help you. So if something goes wrong, we will quickly get you back up and running again.

SUPPLIED:

Maximum availability of spare parts

Our spare parts warehouse always has material with a value of around 6.5 million euros in stock. Each service employee also has a mobile warehouse and can respond to your requirements directly on site. Lengthy procurement times are history.

PAYABLE:

Transparent and fair costs

On average, we manage to eliminate downtimes within 36 hours. At just 79 EUR/h, we are a clear industry leader. Our deployment is only finished when your machine is running again – hand on it!

Facts about POS

… satisfied customers

… Hours running time of our

machines in the market per year

… Euros worth of spare parts in stock

ensures maximum availability

… – i.e. 5µm positioning accuracy

according to DIN EN ISO 230

POS - We are like you:

medium-sized

POS has been supplying machine manufacturers with top-quality machining centres for over 45 years. Thanks to our experience as a machine manufacturer, we know exactly what your requirements are for your part or large series production, mould and model making as well as special machine and tool construction.

Experience in mechanical engineering

We are like you: medium-sized. This means we understand your needs perfectly and have developed fully equipped, stable and affordable machining centres of the highest quality for you here in the “Ländle”.

We also optimise your new machine for your specific processes and offer patented automation solutions.

With a milling machine from POS, you will always process your orders to the highest quality, increase your machine hours and ensure healthy growth and sustainable business success with a future-proof investment.

Make the comparison! You will receive a customised calculation. Whether DMG, Haas, Hedelius, Hermle, Heller, Kunzmann, Mazak, Haas, Reckermann, Spinner or whoever - compare our offer for a 5-axis POSmill with the corresponding equipment from our competitors: