Milling machines & lathes with a difference:

Secure future through full equipment.

Proven:

More stable and precise.

Quality guarantee:

90 % German components.

Service:

Fair, functional and affordable: 79 euros.

In-house patented automation solutions.

Financing: Simple, direct and without a bank.

Full equipment is our basic equipment

We already have almost all conceivable options in the standard equipment of our CNC machining centres, so with POSmill milling machines and POSturn lathes you are not missing any process-securing elements. In addition, you can easily add the right automation solution to your machining center even later.

Discover all powerful machining centers and automation solutions from POS – Full equipment as standard!

POSmill CE 1000

Our multi-talented milling centre -

vertical 3-axis machining centre

x=1,060 mm | y=600 mm | z=600 mm

POSmill E 1600

The great milling multi-talent -

vertical 3-axis machining centre

x=1,600 mm | y=800 mm | z=800 mm

POSmill E 2050

Large and ergonomic -

3-axis (portal) machining centre

x=2,050 mm | y=1,150 mm | z=780 mm

POSmill H 500 U

The all-rounder for all sides -

vertical 5-axis machining centre

x=650 mm | y=850 mm | z=500 mm

POSmill H 800 U (1000 U)

5-sided machining in all materials

vertical 5-axis machining centre

x=670 (1,000) mm | y=820 (1,200) mm | z=600 (700) mm

POSmill H 2200 U

The all-rounder for large parts -

5-axis (portal) machining centre

x=2,200 mm | y=1,400 mm | z=1,000 mm

POSturn E 450 (L)

Handles all materials –

Turning centre with driven tools

x=305 mm | z=750 (1,250) mm

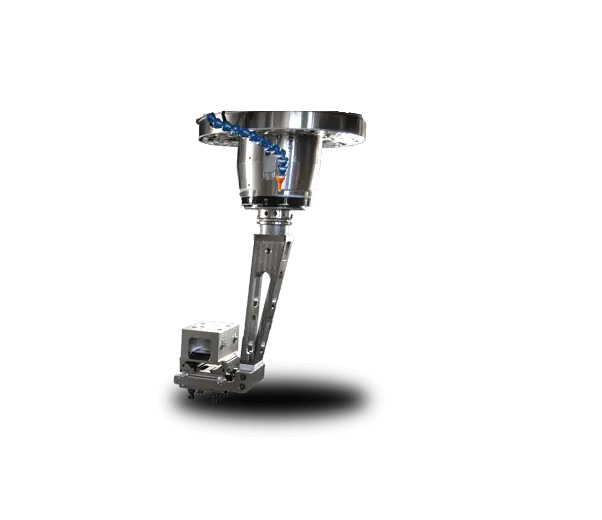

POSrobo R 74 | R 125

The ingenious solution for small parts –

Automation differently!

Space-saving internal solution that utilises the tool changer.

Patented compatible with all POS machines

POSrobo R 500 (i) | R 400

External unit for large parts –

Automation differently!

Range up to 3 m up to 350 kg transfer weight.

Compatible with all POS machines.

The checklist for your machine selection.

The investment in your next machining centre needs to be well considered. Of course, you can compare different machine manufacturers. And we like to make such a comparison! Therefore, we have developed a checklist to help you find the right machine builder.

After almost half a century of experience in the industry, we know the requirements you have as a parts manufacturer or mass producer, mould maker, model maker, special machine builder or toolmaker. POS consistently fulfils these requirements with a concentrated range of fully equipped machines, excellent support and future-proofing right through to the after-market.

Experience in mechanical engineering

Facts

… satisfied customers

… hours of running time of our

machines on the market per year

… Euro value of spare parts in stock

ensures maximum availability

… – so up to 5µm positioning accuracy

according to DIN EN ISO 230

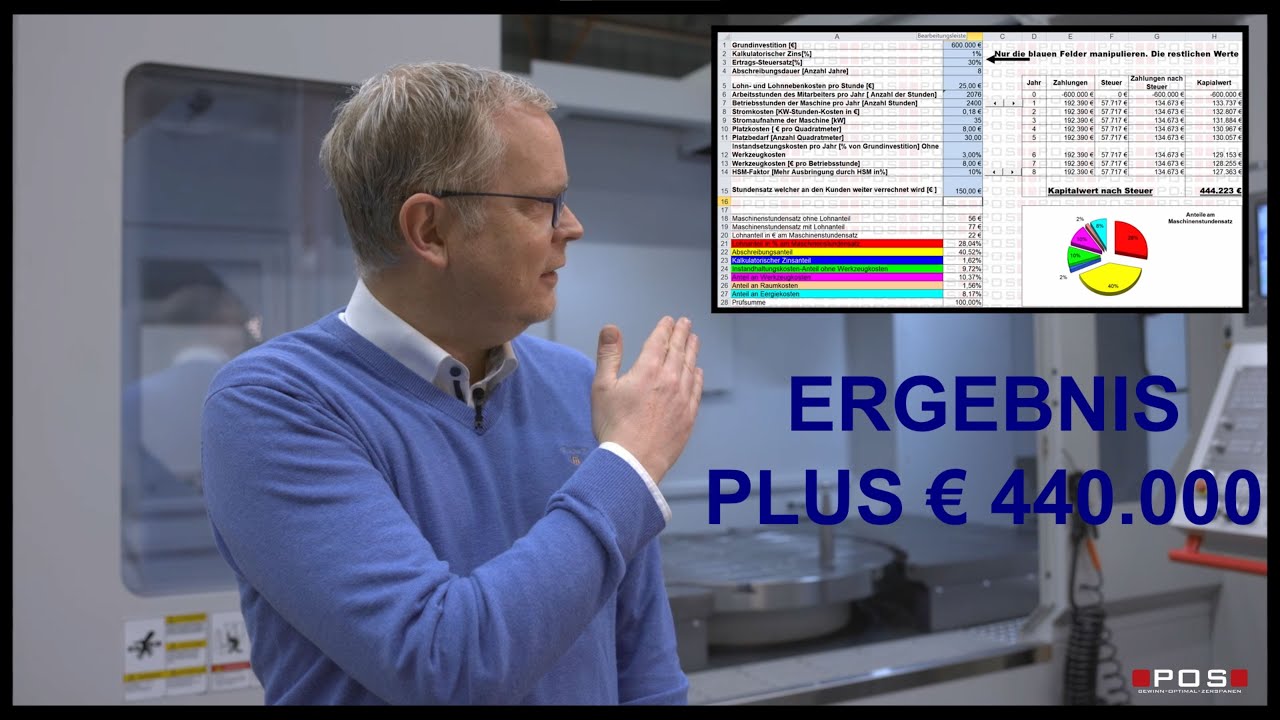

Best milling - The POS tips

POS Tips

Used machines from POS

The motto “everything from a single source” does not stop at the return of your old machine. Upon request, POS will take back your old machine and you will not have to worry about the issues of warranty, subsequent customer, dismantling and removal and possible disposal. Simply carefree!

Used POS machines are of course available from us with the proven POS fidelity guarantee and are therefore safe. Even if you choose a used POS machine. Take a look around: