Milling machines for parts production

Our program for parts production:

POSmill

CE 1000

Our all-rounder.

3-axis milling machine / machining centre

x=1.060 mm | y=600 mm | z=600 mm

POSmill

E 1600

Our all-rounder in large version.

3-axis milling machine / machining centre

x=1.600 mm | y=800 mm | z=800 mm

POSmill

E 2050

Large and ergonomic is no contradiction.

3-axis milling machine / machining centre

x=2.050 mm | y=1.150 mm | z=780 mm

POSmill

H 500 U

Our transformation artist.

5-axis milling machine / machining centre

x=650 mm | y=850 mm | z=500 mm

POSmill

H 800 U

Our all-rounder with safety reserves.

5-axis milling machine / machining centre

x=670 mm | y=820 mm | z=600 mm

POSmill

H 2200 U

Large and highly profitable.

5-axis milling machine /

machining centre

x=2.200 mm | y=1.400 mm | z=1.000 mm

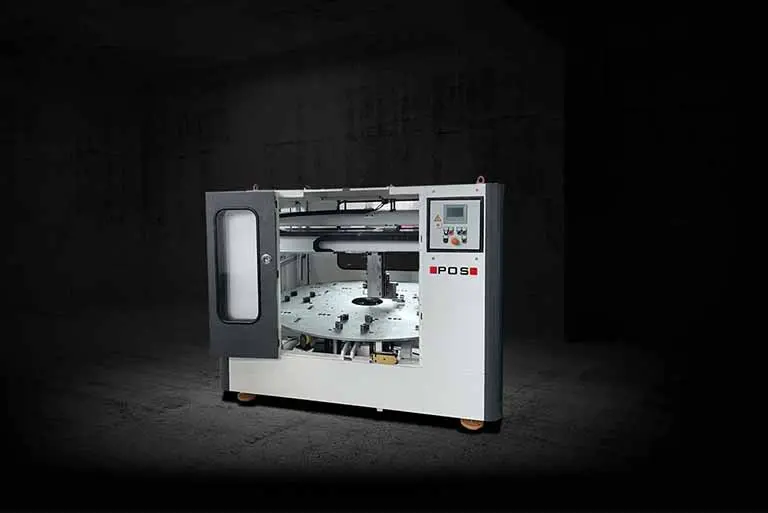

All our milling machines are specially made for the production of parts. The simple operation and the outstanding results will delight you.

They are prepared for every mission. Due to their high stability paired with the best accuracy and dynamics, our milling machines have enough reserves so that you can work profitably at any time.

Our milling machines for parts production

Whether in tool and mould making or in parts production, our milling machines are the solution wherever demanding materials need to be machined with the highest precision. For example, the POSmill E 2050, which masters every task in mould making or in the production of parts.

Of course, at POS you will find far more milling machines that are suitable for the production of parts. Please feel free to contact us. Together with you, we will find the right solution for your suitable machining centre.

Why we just do things differently

With our decades of experience, we can consistently offer you a concentrated product range of a few – but powerful – machine types for parts production. All POS products are already equipped with all essential options by default. This means that you are safely positioned for all future transactions and do not have to depend on the available machine equipment.

POS milling machines are the best for part manufacturers because …

- they can be extended at any time. Up to the 5-axis extension or a suitable automation solution

- highly flexible, thanks to their lavish equipment

- all essential materials can be processed effortlessly

The checklist for your machine choice

The investment in your next machining centre needs to be well considered. Of course, you can compare different machine manufacturers. And we like to make such a comparison! Therefore, we have developed a checklist to help you find the right machine builder.

FAQ

Yes, we even have our own training centre and carry out standard trainings, 5-axis trainings, button trainings and much more. Of course, the training takes place on exactly the same machine as in your company. Incidentally: Our maintenance training offers you high cost savings, since you or your employees can then maintain the machines themselves and repair them again.

Of course. We will provide you with free application diagnosis if required. If you don’t know what to do, call the support team from the application free of charge. The professionals know which tools and clamping devices are optimally compatible with your POS products. This way, you are quickly able to start working again.

Our complete portfolio

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All milling machines and lathes can be extended with our POSrobo automation solutions.

Full equipment is our basic equipment

We already have almost all conceivable options in the standard equipment of our milling machines and lathes. This way, no process-safeguarding elements are omitted. In addition, you can easily add the right automation solution to your machining center even later.