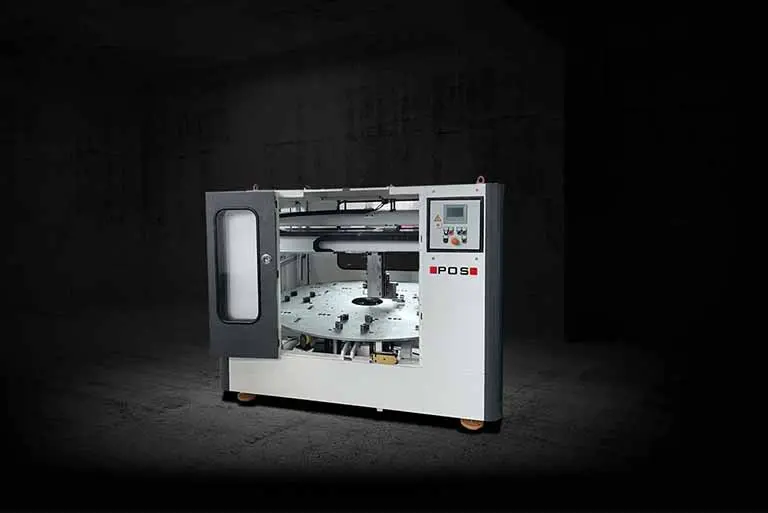

POSmill E 2050 –

Large and ergonomic: The 3-axis portal machining center for the highest demands

3-axis portal milling machine

x=2,050 mm | y=1,150 mm | z=780 mm

Increase precision and productivity in your parts production - The POSmill E 2050 sets new standards in stability, ergonomics, and flexibility

The spacious 3-axis portal milling machining center POSmill E 2050 masters even the most demanding machining tasks with impressive precision and process stability. The innovative portal design with Meehanite cast steel and ribbed structure offers up to 35% more rigidity and vibration damping than comparable machines. Highlights such as 8 massive guide shoes on the machine table, oversized guides on the Y-axis, and high-end equipment ensure consistently excellent results - even with large, heavy components.

- Meehanite cast steel and ribbed structure for maximum stability

- Portal design for consistent precision in every position

- 8 instead of 4 guide shoes on the machine table eliminate vibrations

- 3 oversized linear guides on Y-axis for max. rigidity

- Optimal accessibility through undercut, side doors & large windows

- Ergonomic working space with stainless steel cladding

- High-precision Heidenhain glass scales & low spindle pitch

- 90% German quality components

- Full equipment as standard for maximum future-proofing

Efficient complete machining of large, complex workpieces – this is how you expand your manufacturing capabilities

With its generous working space of 2,200 x 1,000 mm and a table load of up to 3,000 kg, the POSmill E 2050 opens up completely new dimensions in parts production. The powerful portal machining center masters the machining of large, heavy workpieces with high precision in a single setup.

Tool making

100 %

- The 3-axis milling center POSmill E 2050 allows highly productive machining with consistently high surface quality thanks to high travel speeds, massive guides, and dynamic control. Increase your output while reducing unit costs.

- With the portal-style guidance of the milling head, you can realize demanding shapes and complex geometries in one pass. The consistently high rigidity and stability guarantee precise, burr-free, and dimensionally accurate production - even with difficult materials.

- The CNC machine offers ideal conditions for economical series production of large components with minimal setup times, with its dimensions and 3,000 kg table load. Benefit from maximum flexibility and efficiency.

The 3-axis (portal) milling machining centre

POSmill E 2050 in Video

POS machining centers

The 3-axis machining center offers full equipment as standard for maximum future security

The POSmill E 2050 is equipped with a comprehensive package of features right from the factory, leaving nothing to be desired. From the powerful milling spindle to a spacious tool changer to interfaces for automation and measuring technology - benefit from a premium machining center that's ready for immediate use at an attractive price.

- Travel up to 2,050 x 1,150 x 780 mm (X/Y/Z)

- Rapid traverses up to 30 m/min, feed rates up to 10,000 mm/min

- Table size 2,200 x 1,000 mm for workpieces up to 3,000 kg

- Robust 10,000-18,000 rpm milling spindle, ISO 40 / ISO 50 / HSK A63

- High-end control system Heidenhain TNC 640 or Siemens SINUMERIK ONE

- Powerful 40/60-fold tool changer, expandable

- ICS preparation with pressure up to 20 bar

- Preparation for automation, e.g., with POS in-house development POSrobo

- ICS unit with up to 20 bar pressure, interfaces for 3D probe, and much more

Invest in a POS milling machine today and secure the flexibility for future orders. With our machining centers, full equipment is always included. POS: Process Optimisation System!

Always included – the equipment features of the POSmill E 2050 at a glance: Overview:

-

Control system

CONTROL +

INTERFACEWhether gantry or portal design - POS relies on high-end controls from leading manufacturers and a single type of wiring for its 3-axis milling machines. Extensive interfaces and sophisticated preparation make our CNC machining centres real talents for the future - ready for networking, automation and Industry 4.0.

Heidenhain or Siemens high-end controls

Take your production to a new level with high-quality controls from Heidenhain or Siemens. Experience the best performance and intuitive operation.

Take your production to a new level with high-quality controls from Heidenhain or Siemens. Experience the best performance and intuitive operation.Single-type control cabinet

Our single-type control cabinet (e.g. Heidenhain to Heidenhain components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.

Our single-type control cabinet (e.g. Heidenhain to Heidenhain components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.Interfaces: Network connection and multiple USB ports

Simply network your machining centres via the integrated network connection and optimise your data flows. The multiple USB ports offer you maximum flexibility when integrating peripheral devices. Increase the efficiency of your production through optimised connectivity.

Simply network your machining centres via the integrated network connection and optimise your data flows. The multiple USB ports offer you maximum flexibility when integrating peripheral devices. Increase the efficiency of your production through optimised connectivity.Preparation for 3D probes and tool measurement

Use precise 3D probes and tool measurement thanks to our prepared interfaces. This allows you to secure processes and produce to the highest quality.

Use precise 3D probes and tool measurement thanks to our prepared interfaces. This allows you to secure processes and produce to the highest quality.Preparation for external automation POSrobo

With the perfect preparation for our POSrobo automation solutions, you can take your productivity to the next level. Expand your machine flexibly at any time.

With the perfect preparation for our POSrobo automation solutions, you can take your productivity to the next level. Expand your machine flexibly at any time.Air connection on the table via M command for zero-point clamping systems

The integrated air connection on the machine table, controllable via M command, enables the efficient use of zero-point clamping systems. Reduce set-up times, increase your flexibility and sustainably boost the productivity of your production. Changing workpieces has never been so easy.

The integrated air connection on the machine table, controllable via M command, enables the efficient use of zero-point clamping systems. Reduce set-up times, increase your flexibility and sustainably boost the productivity of your production. Changing workpieces has never been so easy.-

Performance

PERFORMANCE +

PRECISIONPowerful milling spindles, precise tool holders and high-resolution path measuring systems - our 3-axis machining centres master even the most demanding tasks. Sophisticated design features and high-quality drives guarantee the best long-term results in CNC machining.

Milling spindle 10,000 rpm with ISO 40

With our powerful milling spindle with 10,000 rpm and precise ISO 40 tool holder, you can machine efficiently and reliably. The air through the spindle per M command reliably prevents clogging and ensures effective chip removal – for maximum productivity and consistently high production quality.

With our powerful milling spindle with 10,000 rpm and precise ISO 40 tool holder, you can machine efficiently and reliably. The air through the spindle per M command reliably prevents clogging and ensures effective chip removal – for maximum productivity and consistently high production quality.Tool changer 40-fold with double gripper

Our 40-position tool changer with double gripper retools your machine in seconds. Whether small milling tools or heavy drills – change up to 40 tools quickly and reliably. Reduce non-productive time and increase your productivity.

Our 40-position tool changer with double gripper retools your machine in seconds. Whether small milling tools or heavy drills – change up to 40 tools quickly and reliably. Reduce non-productive time and increase your productivity.The best Heidenhain glass scales

The high-resolution Heidenhain glass scales ensure maximum positioning accuracy in the long term. The key to precision and repeat accuracy.

The high-resolution Heidenhain glass scales ensure maximum positioning accuracy in the long term. The key to precision and repeat accuracy.air purge for all glass scales; air blast via M-command

Our high-quality glass scales are protected all round: The integrated air purge reliably prevents the ingress of dirt and moisture for permanently precise axis positions. In addition, the air blast the side via the M command keeps the machine windows free of chips and coolant mist – for a clear view of the machining process at all times.

Our high-quality glass scales are protected all round: The integrated air purge reliably prevents the ingress of dirt and moisture for permanently precise axis positions. In addition, the air blast the side via the M command keeps the machine windows free of chips and coolant mist – for a clear view of the machining process at all times.Coolant ring with adjustable nozzles

The coolant ring with individually adjustable nozzles optimally supplies the cutting process with cooling lubricant. For the longest tool life.

The coolant ring with individually adjustable nozzles optimally supplies the cutting process with cooling lubricant. For the longest tool life.-

Safety

OPERATIONAL SAFETY +

RELIABILITYOur large 3-axis machining centre is designed for maximum operational safety and reliability. High-quality cladding, spindle cooling and active switch cabinet protection guarantee the POSmill E 2050 a long service life even under the toughest conditions, e.g. in parts production or in tool and mould making.

Spindle cooling - guided by ambient temperature

Our ambient temperature-controlled spindle cooling ensures constant performance. For reliable processes even with long running times.

Our ambient temperature-controlled spindle cooling ensures constant performance. For reliable processes even with long running times.Active control cabinet cooling

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.Multiple pump system for optimum flushing conditions

Our clever multi-pump system always ensures optimum flushing conditions. For a clean working area and precise results.

Our clever multi-pump system always ensures optimum flushing conditions. For a clean working area and precise results.Operating status light

Our well-visible operating status light informs you of the current machine status at all times. Recognise faults at an early stage.

Our well-visible operating status light informs you of the current machine status at all times. Recognise faults at an early stage.Air reservoir for pressure drop in the air network

The integrated air reservoir protects against unexpected pressure drops in the air network. For continuous production processes without interruptions.

The integrated air reservoir protects against unexpected pressure drops in the air network. For continuous production processes without interruptions.-

Ergonomics

ACCESSIBILITY +

COMFORTThese are the CNC machines from POS: We combine maximum convenience with practical features for efficient set-up and operation. Cleverly designed access points, automated functions and ergonomic operating elements make working on our POSmill E 2050 machining centres much easier.

Workspace with two side doors

Thanks to the two side doors, you have easy access to the entire workspace. Set-up, cleaning and maintenance will be a cinch.

Thanks to the two side doors, you have easy access to the entire workspace. Set-up, cleaning and maintenance will be a cinch.Workspace with two bar lights

Optimum illumination for precise work: The work area is equipped with two powerful rod lights that ensure optimum lighting conditions. Benefit from a shadow-free, detailed view of the workpiece and tool – so you always have a complete overview.

Optimum illumination for precise work: The work area is equipped with two powerful rod lights that ensure optimum lighting conditions. Benefit from a shadow-free, detailed view of the workpiece and tool – so you always have a complete overview.Optimum accessibility due to lower step on the chip conveyor

You can easily reach any point thanks to the lower step. Cleaning and maintenance without contortions.

You can easily reach any point thanks to the lower step. Cleaning and maintenance without contortions.Armoured glass instead of perspex

Shatterproof armoured glass replaces the scratch-sensitive perspex. For a clear view even after years of intensive use.

Shatterproof armoured glass replaces the scratch-sensitive perspex. For a clear view even after years of intensive use.Loading hatch on the roof

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.-

Maintenance

MAINTENANCE +

CLEANLINESSEffective chip conveyance, sophisticated flushing systems and practical cleaning options - so that your CNC machining centre also has a brilliant maintenance record. Smart details and low-maintenance components save valuable time and ensure permanently clean operation in production.

Large chip conveyor with air blast via M command

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.2 x pumps for bed flushing via M command

The double pump for bed flushing with the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.

The double pump for bed flushing with the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.Integrated oil separator (skimmer)

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.Grease centralised lubrication, low-maintenance replacement

Our centralised grease lubrication system optimally supplies all lubrication points – with maintenance-friendly replacement of the lubricant reservoirs. Minimum effort, maximum reliability.

Our centralised grease lubrication system optimally supplies all lubrication points – with maintenance-friendly replacement of the lubricant reservoirs. Minimum effort, maximum reliability.Water gun

Cleaning the work area is a piece of cake with the integrated water gun. For a clean machine in no time at all.

Cleaning the work area is a piece of cake with the integrated water gun. For a clean machine in no time at all.Air gun

Remove chips and dust effectively with the compressed air gun. This will keep your machine permanently clean.

Remove chips and dust effectively with the compressed air gun. This will keep your machine permanently clean.-

Options

OPTIONAL

COMPONENTSExpand your CNC milling machine as required - with customised automation solutions, precise measuring systems or high-performance peripheral devices. We offer you maximum flexibility for your requirements.

Other tool changer capacities

Select the tool changer capacity to suit your range of parts. No matter how much – we have the right solution.

Select the tool changer capacity to suit your range of parts. No matter how much – we have the right solution.3D probe, optionally via infrared or radio

With our precise 3D probes – optionally via infrared or radio – you can measure workpieces quickly and accurately. For the highest quality standards.

With our precise 3D probes – optionally via infrared or radio – you can measure workpieces quickly and accurately. For the highest quality standards.Tool measuring system Infrared or radio

Our tool measuring system checks quickly, wear-free and with maximum accuracy. For consistently dimensionally accurate production results.

Our tool measuring system checks quickly, wear-free and with maximum accuracy. For consistently dimensionally accurate production results.Large ICS unit with belt filter and fine filter - 20 bar or more

Our high-performance ICS unit with belt filter and fine filter guarantees clean cooling lubricant at all times. For optimum cooling and long tool life.

Our high-performance ICS unit with belt filter and fine filter guarantees clean cooling lubricant at all times. For optimum cooling and long tool life.POS-own automation solutions - POSrobo

With the clever POSrobo automation solutions, you can automate your POS machining centres efficiently. Full flexibility from a single source.

With the clever POSrobo automation solutions, you can automate your POS machining centres efficiently. Full flexibility from a single source.External automation solutions according to customer requirements

Realise the automation of your POS machine with external solutions to suit your requirements. We will be happy to assist you.

Realise the automation of your POS machine with external solutions to suit your requirements. We will be happy to assist you.

CONTROL +

INTERFACE

Whether gantry or portal design - POS relies on high-end controls from leading manufacturers and a single type of wiring for its 3-axis milling machines. Extensive interfaces and sophisticated preparation make our CNC machining centres real talents for the future - ready for networking, automation and Industry 4.0.

Heidenhain or Siemens high-end controls

Take your production to a new level with high-quality controls from Heidenhain or Siemens. Experience the best performance and intuitive operation.

Take your production to a new level with high-quality controls from Heidenhain or Siemens. Experience the best performance and intuitive operation.

Single-type control cabinet

Our single-type control cabinet (e.g. Heidenhain to Heidenhain components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.

Our single-type control cabinet (e.g. Heidenhain to Heidenhain components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.

Interfaces: Network connection and multiple USB ports

Simply network your machining centres via the integrated network connection and optimise your data flows. The multiple USB ports offer you maximum flexibility when integrating peripheral devices. Increase the efficiency of your production through optimised connectivity.

Simply network your machining centres via the integrated network connection and optimise your data flows. The multiple USB ports offer you maximum flexibility when integrating peripheral devices. Increase the efficiency of your production through optimised connectivity.

Preparation for 3D probes and tool measurement

Use precise 3D probes and tool measurement thanks to our prepared interfaces. This allows you to secure processes and produce to the highest quality.

Use precise 3D probes and tool measurement thanks to our prepared interfaces. This allows you to secure processes and produce to the highest quality.

Preparation for external automation POSrobo

With the perfect preparation for our POSrobo automation solutions, you can take your productivity to the next level. Expand your machine flexibly at any time.

With the perfect preparation for our POSrobo automation solutions, you can take your productivity to the next level. Expand your machine flexibly at any time.

Air connection on the table via M command for zero-point clamping systems

The integrated air connection on the machine table, controllable via M command, enables the efficient use of zero-point clamping systems. Reduce set-up times, increase your flexibility and sustainably boost the productivity of your production. Changing workpieces has never been so easy.

The integrated air connection on the machine table, controllable via M command, enables the efficient use of zero-point clamping systems. Reduce set-up times, increase your flexibility and sustainably boost the productivity of your production. Changing workpieces has never been so easy.

PERFORMANCE +

PRECISION

Powerful milling spindles, precise tool holders and high-resolution path measuring systems - our 3-axis machining centres master even the most demanding tasks. Sophisticated design features and high-quality drives guarantee the best long-term results in CNC machining.

Milling spindle 10,000 rpm with ISO 40

With our powerful milling spindle with 10,000 rpm and precise ISO 40 tool holder, you can machine efficiently and reliably. The air through the spindle per M command reliably prevents clogging and ensures effective chip removal – for maximum productivity and consistently high production quality.

With our powerful milling spindle with 10,000 rpm and precise ISO 40 tool holder, you can machine efficiently and reliably. The air through the spindle per M command reliably prevents clogging and ensures effective chip removal – for maximum productivity and consistently high production quality.

Tool changer 40-fold with double gripper

Our 40-position tool changer with double gripper retools your machine in seconds. Whether small milling tools or heavy drills – change up to 40 tools quickly and reliably. Reduce non-productive time and increase your productivity.

Our 40-position tool changer with double gripper retools your machine in seconds. Whether small milling tools or heavy drills – change up to 40 tools quickly and reliably. Reduce non-productive time and increase your productivity.

The best Heidenhain glass scales

The high-resolution Heidenhain glass scales ensure maximum positioning accuracy in the long term. The key to precision and repeat accuracy.

The high-resolution Heidenhain glass scales ensure maximum positioning accuracy in the long term. The key to precision and repeat accuracy.

air purge for all glass scales; air blast via M-command

Our high-quality glass scales are protected all round: The integrated air purge reliably prevents the ingress of dirt and moisture for permanently precise axis positions. In addition, the air blast the side via the M command keeps the machine windows free of chips and coolant mist – for a clear view of the machining process at all times.

Our high-quality glass scales are protected all round: The integrated air purge reliably prevents the ingress of dirt and moisture for permanently precise axis positions. In addition, the air blast the side via the M command keeps the machine windows free of chips and coolant mist – for a clear view of the machining process at all times.

Coolant ring with adjustable nozzles

The coolant ring with individually adjustable nozzles optimally supplies the cutting process with cooling lubricant. For the longest tool life.

The coolant ring with individually adjustable nozzles optimally supplies the cutting process with cooling lubricant. For the longest tool life.

OPERATIONAL SAFETY +

RELIABILITY

Our large 3-axis machining centre is designed for maximum operational safety and reliability. High-quality cladding, spindle cooling and active switch cabinet protection guarantee the POSmill E 2050 a long service life even under the toughest conditions, e.g. in parts production or in tool and mould making.

Spindle cooling - guided by ambient temperature

Our ambient temperature-controlled spindle cooling ensures constant performance. For reliable processes even with long running times.

Our ambient temperature-controlled spindle cooling ensures constant performance. For reliable processes even with long running times.

Active control cabinet cooling

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.

Multiple pump system for optimum flushing conditions

Our clever multi-pump system always ensures optimum flushing conditions. For a clean working area and precise results.

Our clever multi-pump system always ensures optimum flushing conditions. For a clean working area and precise results.

Operating status light

Our well-visible operating status light informs you of the current machine status at all times. Recognise faults at an early stage.

Our well-visible operating status light informs you of the current machine status at all times. Recognise faults at an early stage.

Air reservoir for pressure drop in the air network

The integrated air reservoir protects against unexpected pressure drops in the air network. For continuous production processes without interruptions.

The integrated air reservoir protects against unexpected pressure drops in the air network. For continuous production processes without interruptions.

ACCESSIBILITY +

COMFORT

These are the CNC machines from POS: We combine maximum convenience with practical features for efficient set-up and operation. Cleverly designed access points, automated functions and ergonomic operating elements make working on our POSmill E 2050 machining centres much easier.

Workspace with two side doors

Thanks to the two side doors, you have easy access to the entire workspace. Set-up, cleaning and maintenance will be a cinch.

Thanks to the two side doors, you have easy access to the entire workspace. Set-up, cleaning and maintenance will be a cinch.

Workspace with two bar lights

Optimum illumination for precise work: The work area is equipped with two powerful rod lights that ensure optimum lighting conditions. Benefit from a shadow-free, detailed view of the workpiece and tool – so you always have a complete overview.

Optimum illumination for precise work: The work area is equipped with two powerful rod lights that ensure optimum lighting conditions. Benefit from a shadow-free, detailed view of the workpiece and tool – so you always have a complete overview.

Optimum accessibility due to lower step on the chip conveyor

You can easily reach any point thanks to the lower step. Cleaning and maintenance without contortions.

You can easily reach any point thanks to the lower step. Cleaning and maintenance without contortions.

Armoured glass instead of perspex

Shatterproof armoured glass replaces the scratch-sensitive perspex. For a clear view even after years of intensive use.

Shatterproof armoured glass replaces the scratch-sensitive perspex. For a clear view even after years of intensive use.

Loading hatch on the roof

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.

MAINTENANCE +

CLEANLINESS

Effective chip conveyance, sophisticated flushing systems and practical cleaning options - so that your CNC machining centre also has a brilliant maintenance record. Smart details and low-maintenance components save valuable time and ensure permanently clean operation in production.

Large chip conveyor with air blast via M command

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.

2 x pumps for bed flushing via M command

The double pump for bed flushing with the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.

The double pump for bed flushing with the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.

Integrated oil separator (skimmer)

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.

Grease centralised lubrication, low-maintenance replacement

Our centralised grease lubrication system optimally supplies all lubrication points – with maintenance-friendly replacement of the lubricant reservoirs. Minimum effort, maximum reliability.

Our centralised grease lubrication system optimally supplies all lubrication points – with maintenance-friendly replacement of the lubricant reservoirs. Minimum effort, maximum reliability.

Water gun

Cleaning the work area is a piece of cake with the integrated water gun. For a clean machine in no time at all.

Cleaning the work area is a piece of cake with the integrated water gun. For a clean machine in no time at all.

Air gun

Remove chips and dust effectively with the compressed air gun. This will keep your machine permanently clean.

Remove chips and dust effectively with the compressed air gun. This will keep your machine permanently clean.

OPTIONAL

COMPONENTS

Expand your CNC milling machine as required - with customised automation solutions, precise measuring systems or high-performance peripheral devices. We offer you maximum flexibility for your requirements.

Other tool changer capacities

Select the tool changer capacity to suit your range of parts. No matter how much – we have the right solution.

Select the tool changer capacity to suit your range of parts. No matter how much – we have the right solution.

3D probe, optionally via infrared or radio

With our precise 3D probes – optionally via infrared or radio – you can measure workpieces quickly and accurately. For the highest quality standards.

With our precise 3D probes – optionally via infrared or radio – you can measure workpieces quickly and accurately. For the highest quality standards.

Tool measuring system Infrared or radio

Our tool measuring system checks quickly, wear-free and with maximum accuracy. For consistently dimensionally accurate production results.

Our tool measuring system checks quickly, wear-free and with maximum accuracy. For consistently dimensionally accurate production results.

Large ICS unit with belt filter and fine filter - 20 bar or more

Our high-performance ICS unit with belt filter and fine filter guarantees clean cooling lubricant at all times. For optimum cooling and long tool life.

Our high-performance ICS unit with belt filter and fine filter guarantees clean cooling lubricant at all times. For optimum cooling and long tool life.

POS-own automation solutions - POSrobo

With the clever POSrobo automation solutions, you can automate your POS machining centres efficiently. Full flexibility from a single source.

With the clever POSrobo automation solutions, you can automate your POS machining centres efficiently. Full flexibility from a single source.

External automation solutions according to customer requirements

Realise the automation of your POS machine with external solutions to suit your requirements. We will be happy to assist you.

Realise the automation of your POS machine with external solutions to suit your requirements. We will be happy to assist you.

Partnership-based and personal - POS combines almost 50 years of machine building expertise with medium-sized business values

POS stands for tailor-made CNC milling machines and automation solutions "engineered in Germany". Benefit from the comprehensive know-how, flexibility, and first-class service of an owner-managed medium-sized company with almost 50 years of experience in machine tool construction.

We are like you: medium-sized

"For almost 50 years, we have been focusing on the needs of our customers in the fields of parts production, special machine construction, and tool and mould making. This experience goes into every one of our machines, including the POSmill CE 1000. We know what matters: highest quality, reliability, and service that won't let you down. With over 1,200 satisfied customers and more than 2 million machine hours in the market, we are your reliable partner for the future."

- We solve 65% of all downtimes already in the free telephone support. Even on weekends.

- 25 service technicians nationwide with their own mobile spare parts warehouse ensure quick help on-site.

- Spare parts worth 6.5 million EUR are always available in our warehouse to ensure maximum availability of your machines.

- 5 µm positioning accuracy according to DIN EN ISO 230 guarantee highest precision.

Ready for the productivity boost in your parts production?

Request your non-binding quote for the POSmill E 2050 now. Our experts will also be happy to advise you personally on all the details and equipment options of the high-performance 3-axis portal machining centre.

This is how you benefit:

- A POSmill protects your tools & maximizes your machine hours

- Full equipment and premium components as standard at a top price

- 35% more stable, 4 times more accurate, and up to 30% cheaper than comparable CNC portal milling machines

- Partnership-based service with direct, competent contact persons

- In-house financing without paperwork possible via POScapital

* required

Our offer is aimed at business customers. We respect your privacy and process your data exclusively within the framework of a business customer relationship. Your data will be securely managed in accordance with our privacy policy.

Or simply call:

Our other 3-axis machining centers

POSmill CE 1000

Our multi-talented milling machine –

vertical 3-axis machining centre

x=1,060 mm | y=600 mm | z=600 mm

POSmill E 1600

The great milling all-rounder –

vertical 3-axis machining centre

x=1,600 mm | y=800 mm | z=800 mm

POSmill E 2050

Large and ergonomic –

3-axis (portal) machining centre

x=2,050 mm | y=1,150 mm | z=780 mm

Discover all powerful machining centers and automation solutions from POS – Full equipment as standard!

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All machining centres (milling machines and lathes) can be expanded with our POSrobo automation solutions.