Milling machines for model making: When detail is ey

Our program for model making:

POSmill

CE 1000

Our all-rounder.

3-axis milling machine / machining centre

x=1.060 mm | y=600 mm | z=600 mm

POSmill

E 1600

Our all-rounder in large version.

3-axis milling machine / machining centre

x=1.600 mm | y=800 mm | z=800 mm

POSmill

E 2050

Large and ergonomic is no contradiction.

3-axis milling machine / machining centre

x=2.050 mm | y=1.150 mm | z=780 mm

POSmill

H 500 U

Our transformation artist.

5-axis milling machine / machining centre

x=650 mm | y=850 mm | z=500 mm

POSmill

H 800 U

Our all-rounder with safety reserves.

5-axis milling machine / machining centre

x=670 mm | y=820 mm | z=600 mm

POSmill

H 2200 U

Large and highly profitable.

5-axis milling machine /

machining centre

x=2.200 mm | y=1.400 mm | z=1.000 mm

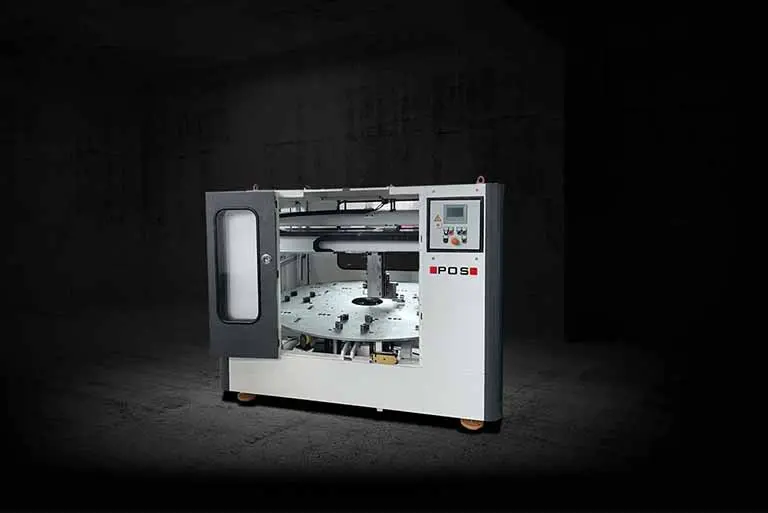

As a model maker, you place the highest demands on your milling machines. Rightly so. After all, your customers expect precise and stable results. On the other hand, your team wants to be able to work as comfortably and flexibly as possible. With the POS milling machines for model builders, you can meet all these requirements.

POS Milling machines for model making …

- also optimally master the milling of dry materials

- are highly flexible in use, work precisely and are stable

- come to terms with all materials such as ureol, brass, steel and aluminium

Milling machines for professional model making

Professional model builders from all over Germany place their trust in our milling machines in order to be able to produce models from different materials. What makes us special: The accuracy of our milling machines in the production of the model components with at the same time simple operation. Even the smallest parts made of ureol or aluminium can be manufactured efficiently with our milling machines for model making.

Our customers come from

- Tool and mould making

- Model making

Realise today your machining centre for the model making of tomorrow

With our flexible systems and milling machines for model making, we can meet even complex requirements – so that you can work quickly and efficiently. Our solutions enable the production of your workpieces from a wide variety of materials, regardless of location. At the same time, we can promise fast production even at peak utilization. Whether it is a 3-axis milling machine or a fully simultaneous 5-axis milling machine: POS has the right machine for your application.

All our milling machines for model making are realized as a complete solution. So you do not have any options to buy, but you buy with certainty. It’s all included in the standard. In addition, all machines are prepared for automation.

The checklist for your machine choice

The investment in your next machining centre needs to be well considered. Of course, you can compare different machine manufacturers. And we like to make such a comparison! Therefore, we have developed a checklist to help you find the right machine builder.

FAQ

Of course. We rely on a high proportion of in-house production and almost exclusively use components made in Germany. Quality components from well-known German manufacturers are virtually our standard. In the value chain, more than 90% of German components are installed in all POS machines. Whether cross table or gantry milling machine: we guarantee high technical availability for every machine.

POS stands for Process Optimization System. Our customers usually approach us because you need a concrete solution to an existing problem. We make this process work and optimise it in the sense of a profitable way of working. At all times, we proceed systematically – for a consistently high output quality.

We have the claim that your users can reliably process demanding materials with all POS products. Whether ureol or aluminium – the POS machines can even reliably machine tool steels, regardless of the hardness of the selected material. At the same time, all our milling machines meet the accuracy requirements according to DIN EN ISO 230.

Our complete portfolio

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All milling machines and lathes can be extended with our POSrobo automation solutions.

Full equipment is our basic equipment

We already have almost all conceivable options in the standard equipment of our milling machines and lathes. This way, no process-safeguarding elements are omitted. In addition, you can easily add the right automation solution to your machining center even later.