POSmill Milling Machining Centers –

Precision and Performance for Your Most Demanding Machining Tasks

3-axis and 5-axis machining centres for the highest demands - developed for maximum stability, accuracy and efficiency. Our CNC milling machines combine innovative technology with robust design to take your productivity to a new level. With full equipment as standard and the flexibility for future automation, you are ideally equipped for the challenges of tomorrow.

Experience the difference: Stability, precision, and future-proofing in one machine

The POSmill machining centres combine innovative technology with robust design to take your machining processes to a new level. From precise 3-axis operations to complex 5-axis simultaneous machining - our milling machines master even the most challenging tasks with flying colours.

Experience maximum precision, rigidity and vibration damping like no other comparable machine. And the best part: Every POSmill machining center comes fully equipped in the base version.

- Unmatched stability: Up to 60% higher rigidity and vibration damping thanks to patented Meehanite cast steel and ribbed design. Benefit from constant cutting behavior and longer tool life - even with the most demanding materials and complex 5-axis machining.

- Highest precision: 4 times more accurate positioning (5µm according to DIN EN ISO 230) through high-quality Heidenhain glass scales and low spindle pitch. Manufacture complex components with the tightest tolerances reliably and repeatably.

- Maximum flexibility: Choose from various designs and sizes - from compact 3-axis to spacious 5-axis milling centers. Large-dimensioned rotary axes without interfering edges enable unrestricted freedom of movement on 5-axis models.

- Fully equipped as standard: Save on expensive retrofitting - our machines come with everything you need for efficient milling. From powerful milling spindles and spacious tool magazines to high-end controls from Heidenhain or Siemens.

- Future-proof automation: Prepared for seamless integration of our innovative POSrobo automation solutions. Increase your utilization flexibly and as needed - without overinvestment.

- 90% German quality components: For long-term availability of spare parts and maximum reliability. Minimise downtimes and benefit from the expertise of leading suppliers.

- Ergonomic design: Spacious working area with stainless steel cladding for easy handling of even large workpieces. Optimize your setup processes and increase work safety.

- Expert support: We solve 65% of all downtimes free of charge by telephone - even at weekends. Our experienced service team ensures maximum machine availability and minimum downtime.

Versatile and powerful: POSmill machining centers master every challenge

POSmill machining centers are the ideal solution for a wide range of manufacturing tasks. Thanks to their robust construction, high precision, and flexible configuration options, they master even the most demanding machining tasks with flying colors.

Parts production

100 %

- Precise parts production: Thanks to high travel speeds, massive guides, and dynamic control, POSmill machining centers enable highly productive machining with consistently high surface quality. Increase your output while reducing unit costs - ideal for efficient series production.Precise parts production: Thanks to high travel speeds, massive guides, and dynamic control, POSmill machining centers enable highly productive machining with consistently high surface quality. Increase your output while reducing unit costs - ideal for efficient series production.

Tool and mould making

100 %

- Complex contours in tool and mould making: The stable design guarantees vibration-free and burr-free production even with demanding contours. Realize high-precision molds and tools in one pass - for minimal rework and maximum cost-effectiveness.Complex contours in tool and mould making: The stable design guarantees vibration-free and burr-free production even with demanding contours. Realize high-precision molds and tools in one pass - for minimal rework and maximum cost-effectiveness.

High volume series production

80 %

- Efficient large-scale production: Highly dynamic drives, powerful spindles, and spacious tool magazines enable long, uninterrupted runtimes. In combination with the optional POSrobo automation solutions, you can realize highly efficient 24/7 production.Efficient large-scale production: Highly dynamic drives, powerful spindles, and spacious tool magazines enable long, uninterrupted runtimes. In combination with the optional POSrobo automation solutions, you can realize highly efficient 24/7 production.

Model making

100 %

- Precision in model making: The combination of high rigidity and high-resolution measuring systems guarantees the best surface finishes and tightest tolerances. Manufacture filigree structures and complex geometries reliably and repeatably.Precision in model making: The combination of high rigidity and high-resolution measuring systems guarantees the best surface finishes and tightest tolerances. Manufacture filigree structures and complex geometries reliably and repeatably.

Special machine construction

100 %

- Flexibility in special machine construction: With generous travels and table loads up to 3,000 kg, POSmill milling centers offer ideal conditions for the economical production of large, complex components. Benefit from maximum flexibility with minimal setup times.Flexibility in special machine construction: With generous travels and table loads up to 3,000 kg, POSmill milling centers offer ideal conditions for the economical production of large, complex components. Benefit from maximum flexibility with minimal setup times.

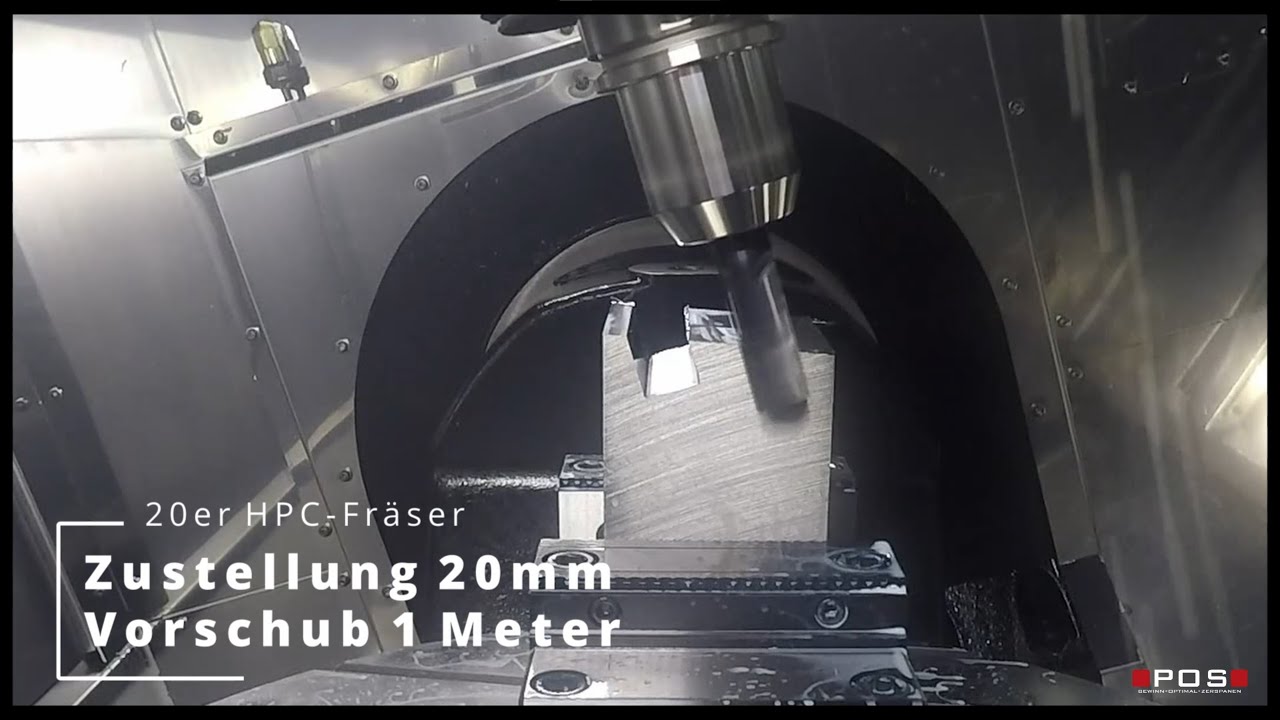

POSmill Machining Centers in Video

POS machining centers

Full equipment as standard - your advantage from the first chip

At POSmill, full equipment really means fully equipped. Our 3- and 5-axis milling centers come standard with premium components and well-thought-out features that guarantee you the highest productivity and precision from day one. Save yourself expensive retrofitting and benefit from a well-thought-out complete package!

Whatever orders await you in the coming years, with POS machining centres you are prepared, because all our CNC machines are already fully equipped as standard. POS: Process Optimisation System!

All-inclusive – already in the basic equipment:

Control + Interface

- High-end controls from Heidenhain or Siemens

- Single-type control cabinet for maximum compatibility

- Extensive interfaces incl. Network and USB

- Preparation for 3D probe and tool measurement

- Trouble-free integration of POSrobo Automation

Performance + Precision

- Powerful milling spindles with up to 18,000 rpm

- High-quality tool holders (ISO 40, HSK-A63 or HSK-A100)

- Best Heidenhain glass scales with sealing air

- Generous tool changer with up to 244 positions

- Torque motors for maximum dynamics in all axes

Stability + Reliability

- Patented Meehanite cast steel for maximum rigidity

- Active control cabinet cooling for permanently trouble-free operation

- Spindle cooling for constant precision even during continuous operation

- Multiple pump system for optimum cooling lubrication conditions

- Passive collision protection to protect the machine and workpiece

Ergonomics + Ease of Use

- Spacious work area with stainless steel interior panelling (by type)

- Automatic roof for easy loading and unloading by crane (by type)

- Optimum accessibility thanks to clever door concepts

- Double LED illumination for perfect visibility

- Ergonomic control panel for fatigue-free working

Maintenance + Cleanliness

- Oversized chip conveyors for reliable chip transport

- Integrated oil separator for long coolant service life

- Low-maintenance centralised grease lubrication

- Flushing and cleaning systems for a clean workspace

Optional Components

- Expandable tool changer capacities for even more flexibility

- 3D probe (infrared or radio) for precise workpiece measurement

- Laser tool measuring system for maximum accuracy and process reliability

- Powerful ICS unit with band filter and fine filter (up to 20 bar or more)

- POSrobo automation solutions for efficient, unmanned production

With the comprehensive, fully equipped POSmill machining centres, you are making a sustainable investment in your future viability. Expand your machine park with these flexible all-rounders today and benefit from the process expertise of a reliable partner.

Milling machining centre: 3- and 5-axis POSmill

POSmill CE 1000

Our multi-talented milling machine –

vertical 3-axis machining centre

x=1,060 mm | y=600 mm | z=600 mm

POSmill E 1600

The great milling all-rounder –

vertical 3-axis machining centre

x=1,600 mm | y=800 mm | z=800 mm

POSmill E 2050

Large and ergonomic –

3-axis (portal) machining centre

x=2,050 mm | y=1,150 mm | z=780 mm

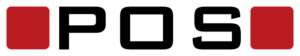

POSmill H 500 U

The all-rounder for all sides –

vertical 5-axis machining centre

x=650 mm | y=850 mm | z=500 mm

POSmill H 800 U (1000 U)

5-sided machining in all materials –

vertical 5-axis machining centre

x=670 (1,000) mm | y=820 (1,200) mm | z=600 (700) mm

POSmill H 2200 U

The all-rounder for large parts –

5-axis (portal) machining centre

x=2.200 mm | y=1.400 mm | z=1.000 mm

Almost 50 years of perfection from passion: Personal. Competent. Reliable.

At POS, your success is our top priority. With almost half a century of experience in machine tool construction, we know exactly what is important in machining. Our expertise flows into every one of our machines - for your productivity and your competitive edge.

We are like you: medium-sized and customer-orientated

"For almost 50 years, we have been focusing on the needs of our customers in the fields of parts production, special machine construction, and tool and mould making. This experience flows into every one of our CNC machining centres. We know what matters: highest quality, reliability, and service that won't let you down. With over 1,200 satisfied customers and more than 2 million machine hours in the market, we are your reliable partner for the future."

- We solve 65% of all downtimes already in the free telephone support. Even on weekends.

- 25 service technicians nationwide with their own mobile spare parts warehouse ensure quick help on-site.

- Spare parts worth 6.5 million EUR are always available in our warehouse to ensure maximum availability of your machines.

- 5 µm positioning accuracy according to DIN EN ISO 230 guarantee highest precision.

Precision meets productivity: Discover your tailor-made POSmill milling machining center

Discover how POSmill milling machining centers can increase your productivity and secure your competitiveness. Request your non-binding quote now and get individual advice from our experts!

This is how you benefit:

- A POSmill protects your tools & maximizes your machine hours

- Attractive price-performance ratio with full equipment and high-quality components as standard

- 35 % more stable, 4 times more accurate and up to 30 % cheaper than the competition - compare!

- Personal advice with efficient, competent & fair service

- In-house financing without paperwork possible via POScapitalIn-house financing without paperwork possible via POScapital

1 optional | * required

Our offer is aimed at business customers. We respect your privacy and process your data exclusively within the framework of a business customer relationship. Your data will be securely managed in accordance with our privacy policy.

Or simply call:

Discover all powerful machining centers and automation solutions from POS – Full equipment as standard!

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All machining centres (milling machines and lathes) can be expanded with our POSrobo automation solutions.