Milling machines for mass production

Our program for mass production:

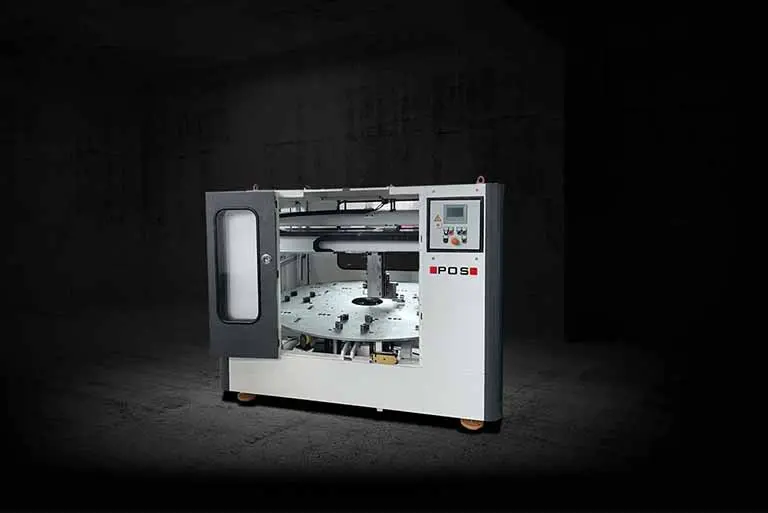

POSmill

CE 1000

Our all-rounder.

3-axis milling machine / machining centre

x=1.060 mm | y=600 mm | z=600 mm

POSmill

E 1600

Our all-rounder in large version.

3-axis milling machine / machining centre

x=1.600 mm | y=800 mm | z=800 mm

POSmill

E 2050

Large and ergonomic is no contradiction.

3-axis milling machine / machining centre

x=2.050 mm | y=1.150 mm | z=780 mm

POSmill

H 500 U

Our transformation artist.

5-axis milling machine / machining centre

x=650 mm | y=850 mm | z=500 mm

POSmill

H 800 U

Our all-rounder with safety reserves.

5-axis milling machine / machining centre

x=670 mm | y=820 mm | z=600 mm

POSmill

H 2200 U

Large and highly profitable.

5-axis milling machine /

machining centre

x=2.200 mm | y=1.400 mm | z=1.000 mm

Choose a POS milling machine for your mass production. Our milling machines work with high flexibility and precision – while maintaining the same quality of the manufactured parts.

With our ALLROUNDER POS CE 1000, you have a machine in use that masters all materials and at the same time can be automated optimally and cost-effectively.

- Quick tool change thanks to double gripper

- High availability due to durable German quality components

- Simple and affordable maintenance intervals

Quality for series production

Milling machines with high-quality components offer real advantages for optimised series production: They guarantee consistent quality on the workpiece. At the same time, you save running costs due to the massive design of POS machines. Their tools last much longer – and that’s cash.

With our milling machines for mass production, we ensure all this. The above-average tool changer capacity ensures high flexibility and maximum safety for complex jobs. At the same time, the minimum heat path of the milling machine forms a consistently high quality of the series parts.

POS milling machines for mass production - the advantages

With POS milling machines for series production, you can achieve effective processing

of your orders. You are assured of short set-up times and cost-effective production.

Always be optimally positioned. Whether you manufacture small series of ten parts or large series of more than 100,000 parts. With our machines, your users mill small, filigree milled parts as well as large, solid components from a wide variety of materials.

- Small and large series

- Short set-up times

- Cost-effective production

- Optimum automation extensions possible at any time

Chip management for your process reliability

It is not only the machine that has to produce the part reliably. At the same time, it is important to remove chips optimally and reliably. Here POS makes no compromises. For example, with the cheapest machine (the POSmill CE 1000) we rely on five separately controlled pumps to master the chips.

With the 5-axis machining centers, we also use a special filter technology that optimally disposes of fine chips and thus minimizes maintenance.

The checklist for your machine choice

The investment in your next machining centre needs to be well considered. Of course, you can compare different machine manufacturers. And we like to make such a comparison! Therefore, we have developed a checklist to help you find the right machine builder.

FAQ

It ensures optimum swath removal and secures the process in series production. At the same time, it is responsible for maintaining cooling and reducing the heat points.

Yes, full equipment is our basic equipment. The large ICZ system, glass scales, but also the electronic handwheel, the water gun and much more are always there.

Yes, every POS milling machine is prepared for automation.

Our complete portfolio

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All milling machines and lathes can be extended with our POSrobo automation solutions.

Full equipment is our basic equipment

We already have almost all conceivable options in the standard equipment of our milling machines and lathes. This way, no process-safeguarding elements are omitted. In addition, you can easily add the right automation solution to your machining center even later.