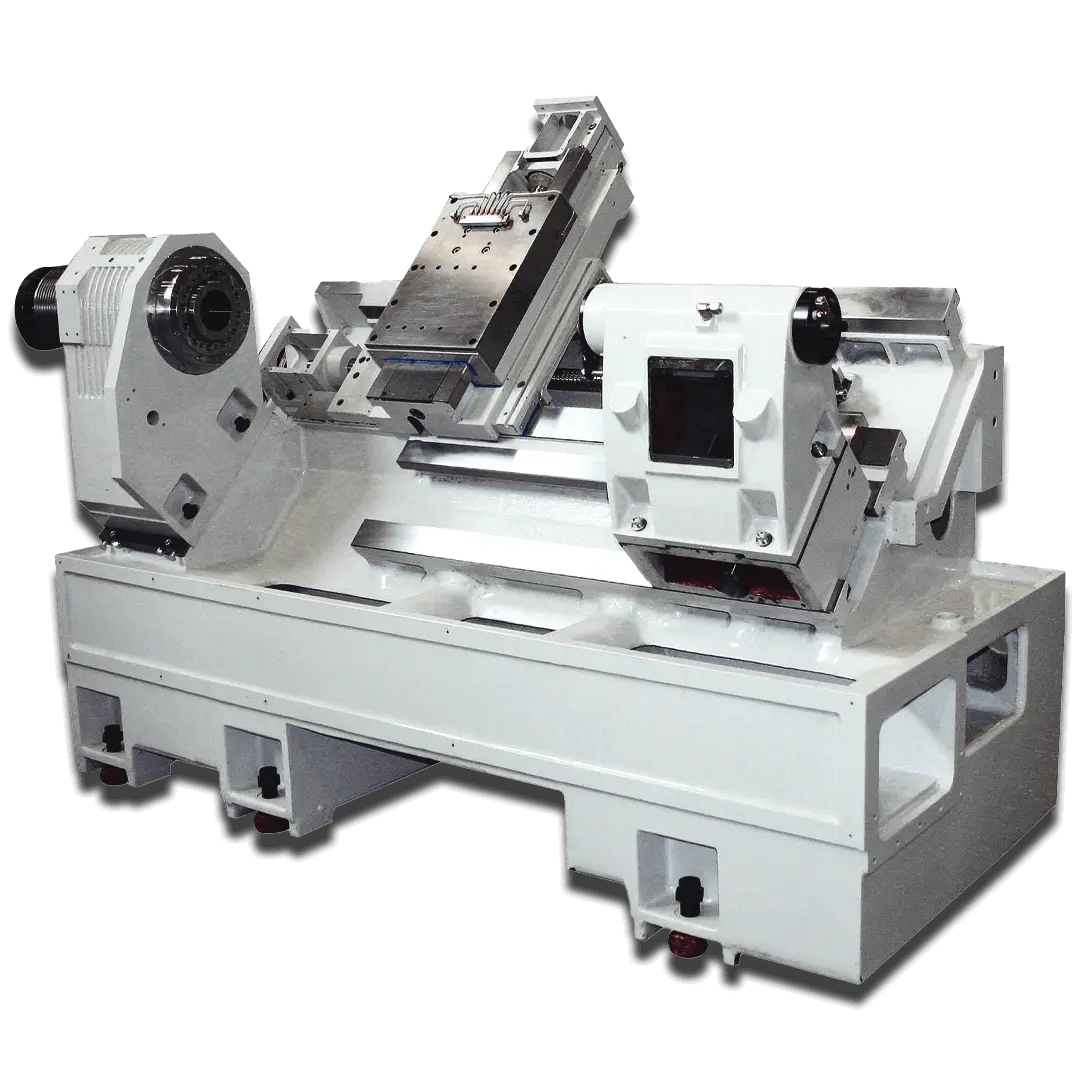

POSturn E 450 –

Masters all materials: The powerful turning center with driven tools

Turn-machining center / lathe

x=305 mm | z=750, 1.250 mm

Machine construction with reserves – highest stability, precision, and reliability for demanding turning tasks

The turn-machining center POSturn E 450 masters even the most difficult materials with impressive process reliability. The patented Meehanite cast steel in combination with the ribbed design provides up to 50% more rigidity and vibration damping than comparable lathes. Thanks to integrated flat guides in all linear axes and a massive slant bed, you benefit from maximum stability in every position. The result: Longer tool life and perfect surfaces.

- Patented Meehanite cast steel and ribbed design for maximum stability

- Continuous flat guides in all linear axes for precision

- Massive slant bed ensures optimal machining conditions

- High-precision Heidenhain glass scales and low spindle pitch

- Fanuc or Siemens high-end control systems for optimal performance

- 90% quality components from German brand manufacturers

- Powder-coated cladding for longevity even under the harshest conditions

- Full equipment as standard for maximum future-proofing

Increase flexibility and cost-effectiveness in turning operations

With the versatile turn-machining center POSturn E 450, you open up completely new possibilities in complete machining. Thanks to the powerful main spindle, 12-position turret with driven tools and travel distances of up to 750 mm, even complex contours are a piece of cake. The simultaneous machining with C-axis enables process-reliable production of demanding components in a single clamping operation.

Tool making

100 %

- The turn-machining center POSturn E 450 machines even the most difficult materials in the highest quality thanks to massive and precise flat guides as well as dynamic feeds. Increase your productivity and reduce scrap and tool costs.

- The powerful 12-station turret with driven tools up to 4500 rpm opens up entirely new possibilities for you: Realize complex turned parts with milled contours, bores, and threads economically in a single clamping operation.

- With the turning center POSturn E 450, you can directly convert your design department's drafts into high-precision components. The combination of massive basic structure, dynamic control, and simultaneously usable C-axis ensures productive manufacturing.

The lathe POSturn E 450 in video

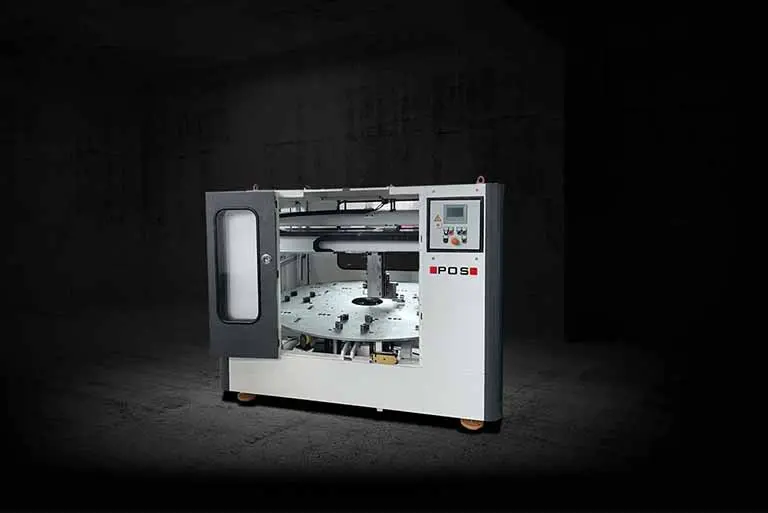

POS machining centers

Highest performance as standard – full equipment for permanently economical machining

The POSturn E 450 combines a variety of high-quality equipment features into a ready-to-use complete solution. From powerful main spindle to generous tool turret to well-thought-out safety and operating options: Benefit from high-end technology at an attractive price.

- Stable travels: up to 750 mm in Z and 485 mm max. turning diameter

- 12-station turret with driven tools up to 4,500 rpm

- Fanuc 32i or Siemens One high-end control system

- Workpieces up to 485 mm turning diameter & 600 mm over bed

- 78 mm spindle bore for longer bar parts

- Interfaces for automation, e.g., bar loader, parts catcher

- Foot switch for safe and convenient chuck change

- Variable pressure control thanks to integrated hydraulic unit

With the POSturn E 450, you are investing in a highly flexible lathe that will meet the highest standards even in the future. Our full equipment saves expensive retrofitting and ensures lasting performance.

Optimally equipped – this is what the POSturn E 450 offers:

-

Control system

CONTROL +

INTERFACEFor its turning centres, POS relies on high-end control systems from leading manufacturers and a single type of wiring. Extensive interfaces and well thought-out preparation make our CNC machines real future talents - ready for networking, automation and Industry 4.0.

Fanuc or Siemens high-end controls

Control your machining processes with the advanced and reliable high-end control from Fanuc or Siemens. Benefit from maximum precision and performance.

Control your machining processes with the advanced and reliable high-end control from Fanuc or Siemens. Benefit from maximum precision and performance.Single-type control cabinet

Our single-type control cabinet (e.g. Fanuc to Fanuc components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.

Our single-type control cabinet (e.g. Fanuc to Fanuc components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.Interfaces: Network connection and USB ports

With the integrated network connection, you can network your machining centres in no time at all and optimise your data flows. The additional USB port enables the fast and uncomplicated transfer of programmes and data as well as the simple connection of external devices and storage media.

With the integrated network connection, you can network your machining centres in no time at all and optimise your data flows. The additional USB port enables the fast and uncomplicated transfer of programmes and data as well as the simple connection of external devices and storage media.Preparation for external bar loader

Our preparation for external bar feeders enables effortless automation of your turning processes. Simply add the right loading solutions to your machine.

Our preparation for external bar feeders enables effortless automation of your turning processes. Simply add the right loading solutions to your machine.-

Performance

PERFORMANCE +

PRECISIONWith the powerful main spindle and precise jaw chuck, you can produce sophisticated turned parts in the shortest possible time with our POSturn turning machining centres. The 12-position turret with driven tools and the best Heidenhain glass scales ensure maximum precision at all times.

Jaw chuck 4,000 rpm, VDI 40

The powerful jaw chuck with 4,000 rpm and VDI 40 masters demanding turning tasks in record time. Experience full power for your production.

The powerful jaw chuck with 4,000 rpm and VDI 40 masters demanding turning tasks in record time. Experience full power for your production.12-station turret with driven tools

Our 12-station turret with driven tools offers maximum flexibility. Complex contours and bores in a single clamping operation.

Our 12-station turret with driven tools offers maximum flexibility. Complex contours and bores in a single clamping operation.Best Heidenhain glass scales including air purge; air blast via M-command

Maximum precision and durability thanks to the best Heidenhain glass scales including air purge. The high-resolution measuring systems ensure permanently precise positioning on all axes. In addition, the side air via M command provides the necessary visibility – it keeps windows free of chips and coolant mist.

Maximum precision and durability thanks to the best Heidenhain glass scales including air purge. The high-resolution measuring systems ensure permanently precise positioning on all axes. In addition, the side air via M command provides the necessary visibility – it keeps windows free of chips and coolant mist.Double brake jaws for C-axis clamping

With the double brake jaws for C-axis clamping, you can machine with absolute torsional rigidity even in difficult positions. Full speed ahead.

With the double brake jaws for C-axis clamping, you can machine with absolute torsional rigidity even in difficult positions. Full speed ahead.Simultaneous machining with C-axis

Use the C-axis for simultaneous milling and turning operations. Realise complex contours in a single clamping process.

Use the C-axis for simultaneous milling and turning operations. Realise complex contours in a single clamping process.-

Safety

OPERATIONAL SAFETY +

RELIABILITYOur POSturn lathes are designed for maximum operational safety and reliability. Foot switches, high-quality panelling, active control cabinet protection and an integrated hydraulic unit guarantee the durability of the CNC lathe, even under the toughest conditions.

Foot switch for chuck

Increase your safety with the practical foot switch for the chuck. Avoid unintentional loosening and protect yourself and your machine.

Increase your safety with the practical foot switch for the chuck. Avoid unintentional loosening and protect yourself and your machine.Active control cabinet cooling

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.Powder coating for longevity

Our high-quality powder coating guarantees a longevity and durability. Your machine stays as good as new for a long time.

Our high-quality powder coating guarantees a longevity and durability. Your machine stays as good as new for a long time.Hydraulic unit for variable pressure control

The built-in hydraulic aggregate allows you to flexibly adjust the pressure to your requirements. Use the optimum power for every application.

The built-in hydraulic aggregate allows you to flexibly adjust the pressure to your requirements. Use the optimum power for every application.-

Ergonomics

ACCESSIBILITY +

COMFORTNo matter which CNC machine from POS: We combine maximum convenience with practical features for efficient set-up and operation. Cleverly designed access points, automated functions and ergonomic operating elements also make working on our turning centres much easier.

Work area with inclined bed for chip removal

The clever inclined bed in the work area allows chips to simply slide off. For a clean machine and trouble-free processes.

The clever inclined bed in the work area allows chips to simply slide off. For a clean machine and trouble-free processes.Workspace with bright illumination

Thanks to the bright illumination of the workspace, you always have a clear view. Optimum visibility makes it easier to set up, check and monitor the machining process.

Thanks to the bright illumination of the workspace, you always have a clear view. Optimum visibility makes it easier to set up, check and monitor the machining process.Ergonomic access to chuck and tailstock

Thanks to the optimised accessibility of the chuck and tailstock, you can set up workpieces in no time at all. Tool changes made easy.

Thanks to the optimised accessibility of the chuck and tailstock, you can set up workpieces in no time at all. Tool changes made easy.Positionable tailstock including extendable quill via M command

Our electrically positionable tailstock with extendable quill simplifies the set-up of long workpieces enormously. Use the M command to move the tailstock to the optimum position and clamp the workpiece with the appropriate quill force. This makes set-up into a piece of cake – for more productivity in parts production.

Our electrically positionable tailstock with extendable quill simplifies the set-up of long workpieces enormously. Use the M command to move the tailstock to the optimum position and clamp the workpiece with the appropriate quill force. This makes set-up into a piece of cake – for more productivity in parts production.Infinitely variable pressure control on the chuck

With the infinitely variable pressure control on the chuck, you can always clamp your workpieces with the optimum pressure. This prevents distortion or damage and ensures process reliability and precision.

With the infinitely variable pressure control on the chuck, you can always clamp your workpieces with the optimum pressure. This prevents distortion or damage and ensures process reliability and precision.Loading hatch on the roof

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.-

Maintenance

MAINTENANCE +

CLEANLINESSEffective chip conveyance, sophisticated flushing systems and practical cleaning options - so that your CNC machining centre also has a brilliant maintenance record. Smart details and low-maintenance components save valuable time and ensure permanently clean operation in production.

Large chip conveyor with air blast via M command

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.Extra pump for bed flushing via M command

The extra pump for bed flushing using the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.

The extra pump for bed flushing using the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.Integrated oil separator (skimmer)

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.-

Options

OPTIONALE

KOMPONENTENErweitern Sie Ihr POSturn Dreh-Zentrum ganz nach Bedarf - mit maßgeschneiderten Automationslösungen, präzisen Messsystemen oder leistungsstarken Peripheriegeräten. Wir bieten Ihnen maximale Flexibilität für ihre Anforderungen.

3D-Taster, wahlweise per Infrarot oder Funk

Mit unseren präzisen 3D-Tastern – wahlweise per Infrarot oder Funk – vermessen Sie Werkstücke schnell und exakt. Für höchste Qualitätsstandards.

Mit unseren präzisen 3D-Tastern – wahlweise per Infrarot oder Funk – vermessen Sie Werkstücke schnell und exakt. Für höchste Qualitätsstandards.Große IKZ-Einheit mit Bandfilter und Feinfilter – 20 bar oder mehr

Unsere leistungsstarke IKZ-Einheit mit Bandfilter und Feinfilter garantiert stets sauberen Kühlschmierstoff. Für beste Kühlung und lange Standzeiten.

Unsere leistungsstarke IKZ-Einheit mit Bandfilter und Feinfilter garantiert stets sauberen Kühlschmierstoff. Für beste Kühlung und lange Standzeiten.Externer Stangenlader nach Kundenwunsch

Materialzuführung, optimale Steuerung und Kontrolle des Materialvorschubs: Ergänzen Sie Ihre Fertigung mit einem externen Stangenlader ganz nach Ihren Anforderungen.

Materialzuführung, optimale Steuerung und Kontrolle des Materialvorschubs: Ergänzen Sie Ihre Fertigung mit einem externen Stangenlader ganz nach Ihren Anforderungen.Automatischer Teilefänger

Der automatische Teilefänger übernimmt das Handling fertiger Werkstücke. Steigern Sie Output und Prozesssicherheit im mannlosen Betrieb.

Der automatische Teilefänger übernimmt das Handling fertiger Werkstücke. Steigern Sie Output und Prozesssicherheit im mannlosen Betrieb.

CONTROL +

INTERFACE

For its turning centres, POS relies on high-end control systems from leading manufacturers and a single type of wiring. Extensive interfaces and well thought-out preparation make our CNC machines real future talents - ready for networking, automation and Industry 4.0.

Fanuc or Siemens high-end controls

Control your machining processes with the advanced and reliable high-end control from Fanuc or Siemens. Benefit from maximum precision and performance.

Control your machining processes with the advanced and reliable high-end control from Fanuc or Siemens. Benefit from maximum precision and performance.

Single-type control cabinet

Our single-type control cabinet (e.g. Fanuc to Fanuc components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.

Our single-type control cabinet (e.g. Fanuc to Fanuc components) guarantees smooth integration of all components. Avoid interface problems and benefit from maximum reliability.

Interfaces: Network connection and USB ports

With the integrated network connection, you can network your machining centres in no time at all and optimise your data flows. The additional USB port enables the fast and uncomplicated transfer of programmes and data as well as the simple connection of external devices and storage media.

With the integrated network connection, you can network your machining centres in no time at all and optimise your data flows. The additional USB port enables the fast and uncomplicated transfer of programmes and data as well as the simple connection of external devices and storage media.

Preparation for external bar loader

Our preparation for external bar feeders enables effortless automation of your turning processes. Simply add the right loading solutions to your machine.

Our preparation for external bar feeders enables effortless automation of your turning processes. Simply add the right loading solutions to your machine.

PERFORMANCE +

PRECISION

With the powerful main spindle and precise jaw chuck, you can produce sophisticated turned parts in the shortest possible time with our POSturn turning machining centres. The 12-position turret with driven tools and the best Heidenhain glass scales ensure maximum precision at all times.

Jaw chuck 4,000 rpm, VDI 40

The powerful jaw chuck with 4,000 rpm and VDI 40 masters demanding turning tasks in record time. Experience full power for your production.

The powerful jaw chuck with 4,000 rpm and VDI 40 masters demanding turning tasks in record time. Experience full power for your production.

12-station turret with driven tools

Our 12-station turret with driven tools offers maximum flexibility. Complex contours and bores in a single clamping operation.

Our 12-station turret with driven tools offers maximum flexibility. Complex contours and bores in a single clamping operation.

Best Heidenhain glass scales including air purge; air blast via M-command

Maximum precision and durability thanks to the best Heidenhain glass scales including air purge. The high-resolution measuring systems ensure permanently precise positioning on all axes. In addition, the side air via M command provides the necessary visibility – it keeps windows free of chips and coolant mist.

Maximum precision and durability thanks to the best Heidenhain glass scales including air purge. The high-resolution measuring systems ensure permanently precise positioning on all axes. In addition, the side air via M command provides the necessary visibility – it keeps windows free of chips and coolant mist.

Double brake jaws for C-axis clamping

With the double brake jaws for C-axis clamping, you can machine with absolute torsional rigidity even in difficult positions. Full speed ahead.

With the double brake jaws for C-axis clamping, you can machine with absolute torsional rigidity even in difficult positions. Full speed ahead.

Simultaneous machining with C-axis

Use the C-axis for simultaneous milling and turning operations. Realise complex contours in a single clamping process.

Use the C-axis for simultaneous milling and turning operations. Realise complex contours in a single clamping process.

OPERATIONAL SAFETY +

RELIABILITY

Our POSturn lathes are designed for maximum operational safety and reliability. Foot switches, high-quality panelling, active control cabinet protection and an integrated hydraulic unit guarantee the durability of the CNC lathe, even under the toughest conditions.

Foot switch for chuck

Increase your safety with the practical foot switch for the chuck. Avoid unintentional loosening and protect yourself and your machine.

Increase your safety with the practical foot switch for the chuck. Avoid unintentional loosening and protect yourself and your machine.

Active control cabinet cooling

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.

Active control cabinet cooling protects your control components from overheating. For permanently trouble-free operation.

Powder coating for longevity

Our high-quality powder coating guarantees a longevity and durability. Your machine stays as good as new for a long time.

Our high-quality powder coating guarantees a longevity and durability. Your machine stays as good as new for a long time.

Hydraulic unit for variable pressure control

The built-in hydraulic aggregate allows you to flexibly adjust the pressure to your requirements. Use the optimum power for every application.

The built-in hydraulic aggregate allows you to flexibly adjust the pressure to your requirements. Use the optimum power for every application.

ACCESSIBILITY +

COMFORT

No matter which CNC machine from POS: We combine maximum convenience with practical features for efficient set-up and operation. Cleverly designed access points, automated functions and ergonomic operating elements also make working on our turning centres much easier.

Work area with inclined bed for chip removal

The clever inclined bed in the work area allows chips to simply slide off. For a clean machine and trouble-free processes.

The clever inclined bed in the work area allows chips to simply slide off. For a clean machine and trouble-free processes.

Workspace with bright illumination

Thanks to the bright illumination of the workspace, you always have a clear view. Optimum visibility makes it easier to set up, check and monitor the machining process.

Thanks to the bright illumination of the workspace, you always have a clear view. Optimum visibility makes it easier to set up, check and monitor the machining process.

Ergonomic access to chuck and tailstock

Thanks to the optimised accessibility of the chuck and tailstock, you can set up workpieces in no time at all. Tool changes made easy.

Thanks to the optimised accessibility of the chuck and tailstock, you can set up workpieces in no time at all. Tool changes made easy.

Positionable tailstock including extendable quill via M command

Our electrically positionable tailstock with extendable quill simplifies the set-up of long workpieces enormously. Use the M command to move the tailstock to the optimum position and clamp the workpiece with the appropriate quill force. This makes set-up into a piece of cake – for more productivity in parts production.

Our electrically positionable tailstock with extendable quill simplifies the set-up of long workpieces enormously. Use the M command to move the tailstock to the optimum position and clamp the workpiece with the appropriate quill force. This makes set-up into a piece of cake – for more productivity in parts production.

Infinitely variable pressure control on the chuck

With the infinitely variable pressure control on the chuck, you can always clamp your workpieces with the optimum pressure. This prevents distortion or damage and ensures process reliability and precision.

With the infinitely variable pressure control on the chuck, you can always clamp your workpieces with the optimum pressure. This prevents distortion or damage and ensures process reliability and precision.

Loading hatch on the roof

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.

The loading hatch in the roof allows workpieces to be conveniently loaded by crane. Clamp heavy parts effortlessly and safely.

MAINTENANCE +

CLEANLINESS

Effective chip conveyance, sophisticated flushing systems and practical cleaning options - so that your CNC machining centre also has a brilliant maintenance record. Smart details and low-maintenance components save valuable time and ensure permanently clean operation in production.

Large chip conveyor with air blast via M command

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.

Our generously dimensioned chip conveyor reliably transports even large quantities out of the workspace. The integrated air-blast function using the M command effortlessly removes even stubborn chips – for a clean machine and trouble-free production. Workpieces, clamping devices and the interior remain permanently clean.

Extra pump for bed flushing via M command

The extra pump for bed flushing using the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.

The extra pump for bed flushing using the M command cleans even the most stubborn dirt. For a clean machine at the end of every programme.

Integrated oil separator (skimmer)

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.

The integrated oil separator reliably removes impurities from the cooling lubricant. For optimum cooling performance and long service life.

OPTIONALE

KOMPONENTEN

Erweitern Sie Ihr POSturn Dreh-Zentrum ganz nach Bedarf - mit maßgeschneiderten Automationslösungen, präzisen Messsystemen oder leistungsstarken Peripheriegeräten. Wir bieten Ihnen maximale Flexibilität für ihre Anforderungen.

3D-Taster, wahlweise per Infrarot oder Funk

Mit unseren präzisen 3D-Tastern – wahlweise per Infrarot oder Funk – vermessen Sie Werkstücke schnell und exakt. Für höchste Qualitätsstandards.

Mit unseren präzisen 3D-Tastern – wahlweise per Infrarot oder Funk – vermessen Sie Werkstücke schnell und exakt. Für höchste Qualitätsstandards.

Große IKZ-Einheit mit Bandfilter und Feinfilter – 20 bar oder mehr

Unsere leistungsstarke IKZ-Einheit mit Bandfilter und Feinfilter garantiert stets sauberen Kühlschmierstoff. Für beste Kühlung und lange Standzeiten.

Unsere leistungsstarke IKZ-Einheit mit Bandfilter und Feinfilter garantiert stets sauberen Kühlschmierstoff. Für beste Kühlung und lange Standzeiten.

Externer Stangenlader nach Kundenwunsch

Materialzuführung, optimale Steuerung und Kontrolle des Materialvorschubs: Ergänzen Sie Ihre Fertigung mit einem externen Stangenlader ganz nach Ihren Anforderungen.

Materialzuführung, optimale Steuerung und Kontrolle des Materialvorschubs: Ergänzen Sie Ihre Fertigung mit einem externen Stangenlader ganz nach Ihren Anforderungen.

Automatischer Teilefänger

Der automatische Teilefänger übernimmt das Handling fertiger Werkstücke. Steigern Sie Output und Prozesssicherheit im mannlosen Betrieb.

Der automatische Teilefänger übernimmt das Handling fertiger Werkstücke. Steigern Sie Output und Prozesssicherheit im mannlosen Betrieb.

Partnership-based, precise, personal - manufacturing companies have relied on POS for almost 50 years

POS stands for tailor-made CNC turn-mill centers "engineered in Germany". Benefit from the comprehensive know-how, flexibility, and first-class service of an owner-managed medium-sized company with almost 50 years of experience in machine tool construction.

We are like you: medium-sized

"For almost 50 years, we have been focusing on the needs of our customers in the fields of parts production, special machine construction, and tool and mould making. This experience goes into every one of our machines, including the POSmill CE 1000. We know what matters: highest quality, reliability, and service that won't let you down. With over 1,200 satisfied customers and more than 2 million machine hours in the market, we are your reliable partner for the future."

- We solve 65% of all downtimes already in the free telephone support. Even on weekends.

- 25 service technicians nationwide with their own mobile spare parts warehouse ensure quick help on-site.

- Spare parts worth 6.5 million EUR are always available in our warehouse to ensure maximum availability of your machines.

- 5 µm positioning accuracy according to DIN EN ISO 230 guarantee highest precision.

Ready for a new era of efficient complete turning?

Request your individual quote for the POSturn E 450 now and receive all technical details! Our experts will be happy to advise you personally on all specifications and equipment options of the powerful 5-axis machining centers.

This is how you benefit:

- A POSturn protects your tools & maximises your machine hours

- Full equipment with premium components as standard at a top price

- 35 % more stable, 4 times more accurate and up to 30 % cheaper than comparable turning centres

- Partnership-based service with direct, competent contact persons

- In-house financing without paperwork possible via POScapital

* required

Our offer is aimed at business customers. We respect your privacy and process your data exclusively within the framework of a business customer relationship. Your data will be securely managed in accordance with our privacy policy.

Or simply call:

Your CNC machine park with full equipment - POS offers individual milling, turning, and automation solutions for your production

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All machining centres (milling machines and lathes) can be expanded with our POSrobo automation solutions.