Milling machines for mould making

Our programme for mould making:

POSmill

CE 1000

Our all-rounder.

3-axis milling machine / machining centre

x=1.060 mm | y=600 mm | z=600 mm

POSmill

E 1600

Our all-rounder in large version.

3-axis milling machine / machining centre

x=1.600 mm | y=800 mm | z=800 mm

POSmill

E 2050

Large and ergonomic is no contradiction.

3-axis milling machine / machining centre

x=2.050 mm | y=1.150 mm | z=780 mm

POSmill

H 500 U

Our transformation artist.

5-axis milling machine / machining centre

x=650 mm | y=850 mm | z=500 mm

POSmill

H 800 U

Our all-rounder with safety reserves.

5-axis milling machine / machining centre

x=670 mm | y=820 mm | z=600 mm

POSmill

H 2200 U

Large and highly profitable.

5-axis milling machine /

machining centre

x=2.200 mm | y=1.400 mm | z=1.000 mm

If one separates the phrase mould making, the result is two words: Mould and Making. You know better than we do that nowadays you have less and less time to touch up a mould. The parts must fit when they come from the machine. That’s where POS comes in.

We have designed the drive train especially for mould making. From basic accuracy to the ball screws with low pitch to the best glass scale, we ensure that you receive matching parts at the touch of a button. This allows you to reduce the time-consuming manual work to a minimum.

The correct shape is sometimes due to the fact that we use the best control technology. Coupled with optimal axis optimization, you get the best surface qualities.

Advantages for mould making:

- Best contour accuracies

- Standard accuracies that you can only purchase as an option from the competition.

- Whether graphite, copper or tool steel - your POS will reliably process the material

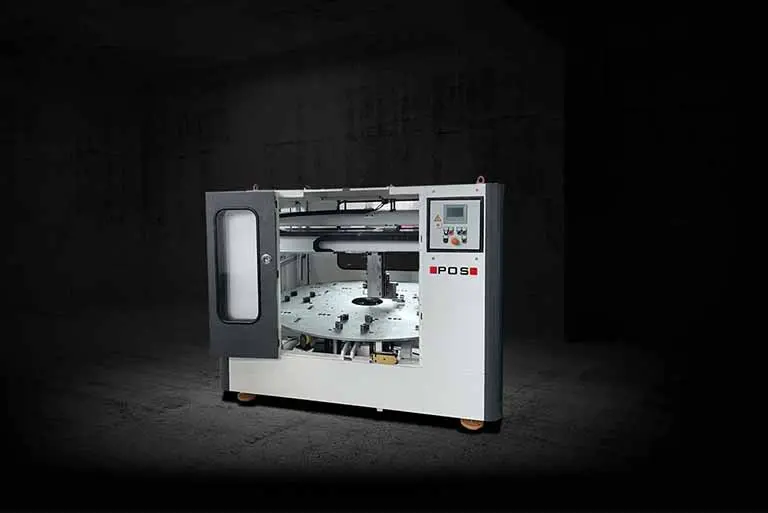

A modern machining centre is the basis

An appropriate machining centre is part of a modern mould making operation. You can meet the constantly growing quality requirements with a POS machining centre. And that’s what you get from us.

We find the right milling machines for your mould making. But that’s not all: We are also happy to take over the training of your staff and bring you to an even better level in terms of milling technology. Of course, our team is always there for you if you have any questions or other concerns.

High-precision work with POS milling machines for mould making

In mould making, the smallest, highly precise radii are required from milling. Especially when it comes to the milling of small cavities and high-gloss surfaces.

We want to optimise your mould-making processes – and thus make you competitive for the future. With our milling machines and portal milling machines, your users can mill without the need for reworking. This saves you valuable time in production and allows you to work economically.

- Accurate results in accelerated processes

- Automation of processes possible with in-house POS solution

- Solutions with an excellent price-performance ratio

Our service promise for mould making

Installed POS machines on the market are in operation for more than 2,000,000 hours per year. This is only possible because of our

- Immediate telephone diagnosis

- High availability of spare parts

- Quick response times

- Professional service technician expertise

The checklist for your machine choice

The investment in your next machining centre needs to be well considered. Of course, you can compare different machine manufacturers. And we like to make such a comparison! Therefore, we have developed a checklist to help you find the right machine builder.

FAQ

Yes, that’s what our experience shows. Our trained service technicians start a quick telephone diagnosis in the event of failures. 65% of downtimes are solved on the phone free of charge and immediately. In addition, almost all spare parts are available from us. A spare parts stock of > 6.5 million euros ensures availability. Conservative product development ensures high technical availability.

We use cast steel as the base body. Therefore, POS machines bring about 30% more mass to the scale than competing products. Advantages: Vibrations are reduced. At the same time, your tool life decreases while process reliability increases.

Yes, we rely on standard components from Germany for the benefit of our customers and not on components manufactured specifically for the manufacturer. This way, we are obliged to offer fair prices and, in an absolute emergency, we get them on the free market. Have you ever wondered where you can get a round protective glass pane made of bulletproof glass? Correct! Only from the manufacturer. And so they can also set the price. Our glass panes are simply square. But fair!

Our complete portfolio

- All

- 3-axis

- 5-axis

- Automation

- Lathes

- Machining Centre

- Milling machines

POSmill CE 1000 | vertical 3-axis all-round machining center

POSmill E 1600 | vertical 3-axis machining center for parts production

POSmill E 2050 | 3-axis portal machining center for large workpieces

POSmill H 500 U | 5-axis machining center for demanding machining tasks

POSmill H 800 U | 1000 U | 5-axis machining centers for demanding manufacturing tasks

POSmill H 2200 U | 5-axis portal machining center for large workpieces

POSturn E 450 | Versatile CNC turning center for economical complete machining

POSrobo R 74 | R 125 – Efficient small parts automation for POSmill machining centers

POSrobo R 500 – The flexible, modular automation solution for POSmill machining centers

All milling machines and lathes can be extended with our POSrobo automation solutions.

Full equipment is our basic equipment

We already have almost all conceivable options in the standard equipment of our milling machines and lathes. This way, no process-safeguarding elements are omitted. In addition, you can easily add the right automation solution to your machining center even later.